Precision Edge Finishing: A Standard for Deburring & Edge Rounding

From Ambiguity to Precision: A Standard for Deburring & Edge Rounding

In the world of custom stainless steel fabrication, few details cause more frustration, rework, and financial loss than the condition of a part’s edge. For decades, engineers have relied on vague notes like “break all sharp edges” or “deburr complete” on technical drawings. While well-intentioned, these phrases are subjective and create a high-risk environment where interpretation replaces objective criteria, leading to inconsistent product quality and costly disputes.

At Northern Manufacturing, we believe achieving predictable quality is a science. This philosophy reflects our core value to Strive For Excellence by blending old-world craftsmanship with cutting-edge technology. It requires a systematic approach that combines a precise language for specification with advanced technology for execution. This article will walk you through our robust framework, explaining how we move beyond ambiguity to deliver the exact edge finish your application demands, every single time.

The Expert’s Language: Understanding ISO 13715

To eliminate subjectivity, the global manufacturing community has a dedicated international standard:

ISO 13715, “Technical product documentation — Edges of undefined shape — Indication and dimensioning”. This standard provides a precise, symbolic language for defining the condition of an edge that isn’t a formally dimensioned feature.

While this standard is technically perfect for defining an edge, its direct application can be counterproductive for those not versed in its nuances. Expecting every customer to become fluent in the complexities of ISO 13715 is impractical. This recognition is a cornerstone of our ISO 9001:2015 certified quality system, which mandates creating robust, clear processes that prevent ambiguity. This led us to develop a more effective strategy for our customers.

Northern’s Solution: A Process-Controlled Classification System

To bridge the gap between technical rigor and customer clarity, we’ve established a simplified, three-tier classification system. It acts as a “translation layer” for the ISO standard, transforming a complex negotiation into a clear selection from a menu of options. When you choose a class, you are selecting a finish that is backed by a precise, internally managed ISO 13715 specification.

|

Edge Class |

Description |

Best For |

ISO 13715 Spec |

|---|---|---|---|

|

Class 3 |

Clean cut laser edge with all burrs removed |

Internal brackets, non-handled components, and edges that will be welded or otherwise not exposed. |

+0 |

|

Class 2 |

Edges are minimally broken from square |

Exposed edges, operator-handled parts, and assemblies where fit and finish are key to product quality. |

-0.1/-0.6 |

|

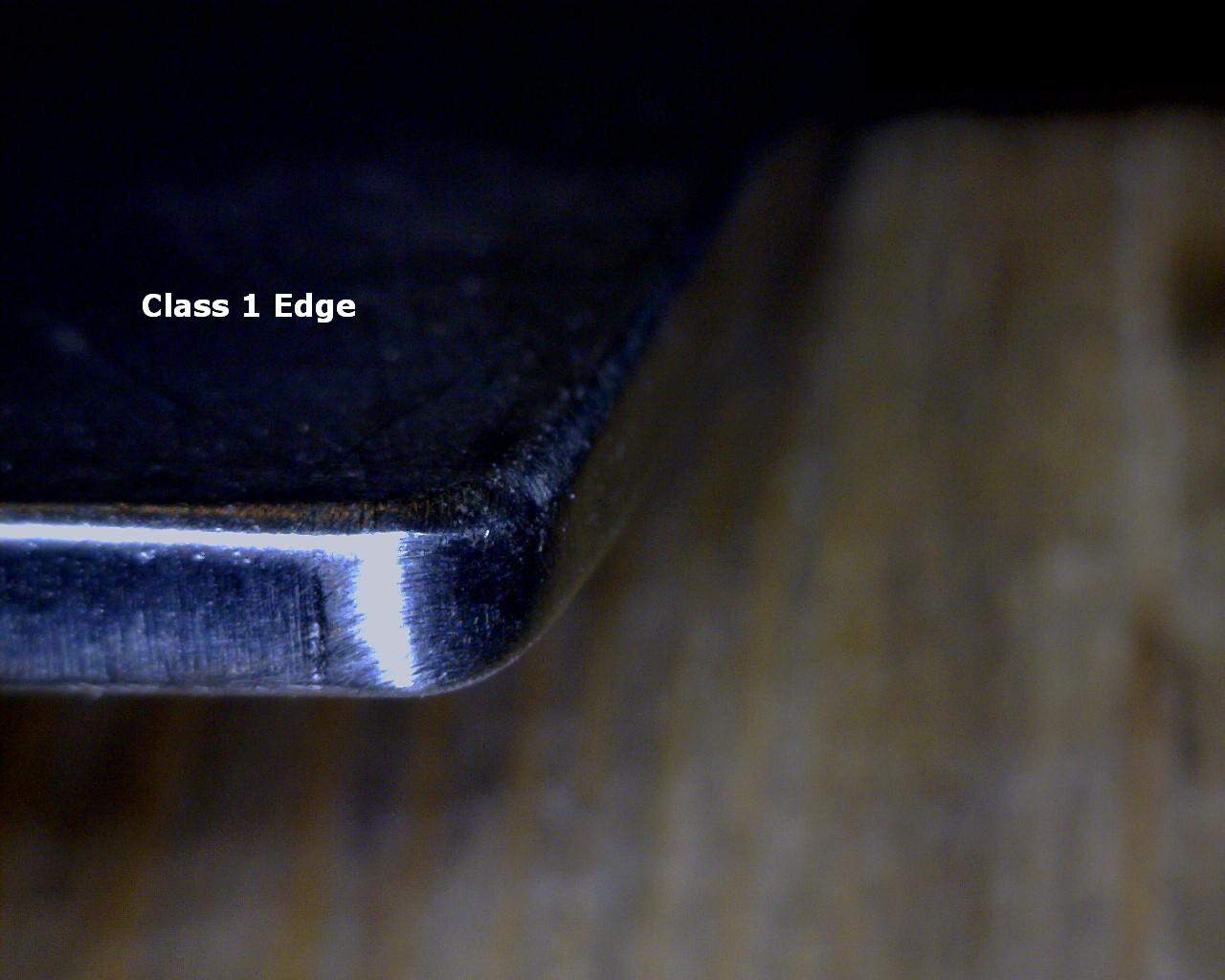

Class 1 |

Radiused safety edge for critical applications |

Parts with safe handling requirements, cable pass-throughs, components that require a smooth sealing surface, or parts with specific aerodynamic or fluid-dynamic needs. |

-0.3/-0.6 |

We encourage our partners to specify the required edge class during the design phase. This allows us to provide the most accurate quote and ensures Design for Manufacturing (DFM) principles are applied, preventing costly post-fabrication changes.

From Specification to Execution: Our Automated Edge Processing

Specifying a Class 1, 2, or 3 finish is only half the battle. Consistently achieving it is what truly sets a fabricator apart. A reliance on final inspection to verify every inch of an edge is inefficient and often impractical. The modern, reliable solution is process control. Instead of relying on inspection to catch errors, we use advanced automated systems to prevent them, ensuring the manufacturing process itself is so stable that the desired outcome is a predictable result.

Our investment in technology like the Lissmac SBM-L G1S2 deburring and edge rounding machine is central to this philosophy. This precision finishing system uses a combination of sanding belts for primary deburring and oscillating abrasive brushes to apply a uniform, rounded edge to the entire part contour—top and bottom, inside and out—all in a single pass.

The critical advantage is repeatability. We develop and document a specific “process recipe” for each combination of material, thickness, and required edge class. This recipe digitally controls every key parameter to guarantee the result. This process control is crucial across our full range of materials, from 300-series austenitic stainless steels to more challenging materials like Duplex 2205 and high-nickel alloys such as AL-6XN, each requiring a unique, validated process recipe to achieve the specified edge condition. When we manufacture your parts, we don’t rely on subjective judgment; we load a validated program scientifically designed to produce an edge that conforms to your specified class.

Since 1951, we have built our reputation on solving complex challenges by continuously refining our processes. By implementing this comprehensive system, we eliminate the costly cycle of rework and disputes, transforming a common industry problem into a competitive advantage for our customers.

Discuss Your Fabrication Challenge with Our Engineering Team

Partner with a fabricator that protects your investment. Submit your drawings to our team for a technical review and a comprehensive quote that reflects the true cost of quality.