Beyond the Blueprint: A Guide to Achieving Manufacturing Certainty in Stainless Steel Precision Sheet Metal Fabrication

Introduction: The High Stakes of “Almost Perfect”

Consider a complex, skid-mounted system destined for a pharmaceutical cleanroom. During final assembly, your team discovers a critical stainless steel frame is warped by a mere 3 millimeters. This single, seemingly minor deviation triggers a cascade of costly problems: precision-machined mounting points are misaligned, sanitary piping connections are strained, and the entire unit no longer fits its designated footprint. The project timeline is jeopardized, budgets are strained, and credibility are on the line—all because a component was “almost perfect.”

For modern Original Equipment Manufacturers (OEMs), the primary challenge is not just designing an innovative product, but ensuring the physical reality perfectly mirrors the digital design. This is especially true when working with a uniquely demanding material like stainless steel. Conventional fabrication methods, which depend on manual interpretation and post-process inspection, introduce an unacceptable level of risk.

True manufacturing precision is not a dimension confirmed by a final inspection report. It is a philosophy embedded in the entire fabrication process—a system engineered to deliver certainty by designing out human variability from the start. This guide outlines the principles of this modern, digitally-driven approach and explains how it produces not just parts, but predictable, successful outcomes.

The Precision Imperative: Why Stainless Steel Changes the Rules

While all metal fabrication demands accuracy, the unique metallurgical properties of stainless steel amplify the consequences of inadequate process control. Mitigating these material-specific challenges is the first step toward achieving genuine precision.

The Language of Precision

Standard fabrication often operates with tolerances measured in millimeters, which is sufficient for many applications. However, for complex machinery and high-performance equipment, this is inadequate. Precision fabrication functions in the realm of microns ($µm$), a level of accuracy essential for the seamless integration of fabricated components with high-tolerance parts like CNC-machined interfaces, bearings, and actuators.

The Stainless Steel Challenge: Distortion & Stress

Austenitic stainless steels like 304 and 316 have a coefficient of thermal expansion roughly 50% greater than carbon steel but exhibit lower thermal conductivity. In practice, this means heat from welding concentrates in the Heat-Affected Zone (HAZ), causing significant expansion. As the material cools and contracts, this localized movement generates powerful internal stresses that lead to warping and distortion.

The Work Hardening Problem

Austenitic stainless steel grades are known to work-harden rapidly. During mechanical operations like bending or forming, the material’s crystalline structure is altered, making it stronger but less ductile. Without precisely calibrated equipment and deep process knowledge, work hardening can cause unpredictable springback, dimensional drift, and even micro-fractures that compromise a part’s long-term integrity.

Failing to master these challenges has severe consequences: poor fit-up during assembly, compromised structural integrity from locked-in stress, and diminished corrosion resistance in the finished product.

Our Philosophy: Building a World Without Tape Measures

The traditional fabrication workflow is a reactive cycle of manual steps: a layout is drawn by hand, a part is cut and formed, its dimensions are checked with a tape measure, and it is reworked until it conforms. This paradigm is fundamentally flawed because it treats precision as a feature to be inspected in, rather than a quality to be built in.

Our philosophy is different. We utilize a seamless digital thread to build unwavering quality into every component from the very first operation. The process is governed by data, not by manual measurement.

Our Embodiment of “Built-In Quality”

This philosophy is not an abstract concept; it is realized every day through the technology and processes on our 160,000+ sq. ft. shop floor.

- CAD to Command: Our process begins with your 3D model, which becomes the single source of truth fed directly into our CAM software. This eradicates the primary source of human error by eliminating manual data entry and blueprint interpretation. These digital instructions are then sent directly to our advanced CNC equipment, like our 12,000 Watt Trumpf FiberLaser, ensuring the first cut is dimensionally perfect.

- Error-Proofing Layout & Fit-Up: Manual layout is obsolete in a modern precision environment.

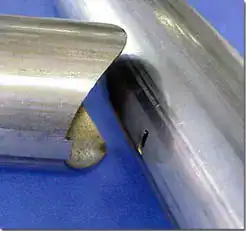

- Laser Etching: We use our cutting lasers to etch part numbers, precise bend lines, and assembly markers directly onto component surfaces. This makes manual layout unnecessary, ensures foolproof part identification, and provides welders with unambiguous alignment guides.

- Self-Locating Geometry: We design components with interlocking slots and tabs wherever possible. This “poka-yoke” (mistake-proofing) technique creates self-aligning assemblies that guarantee perfect positioning and rigidity before welding begins, drastically reducing the need for complex and costly fixtures.

- Guided Assembly with Laser Projection: For intricate weldments, our digital thread extends to the final assembly step. Laser projectors cast full-scale, true-to-spec outlines from the 3D model directly onto the workpiece. This provides our AWS and ASME-certified welders with an exact visual guide for component placement, ensuring a level of positional accuracy impossible to achieve with manual methods.

The result of this digitally-driven system is a fabrication process that is repeatable, verifiable, and inherently precise. It eliminates guesswork and minimizes human error, transforming precision from an aspiration into an operational certainty.

Mastering Stainless Steel Integrity: Beyond Form and Fit

For stainless steel, precision extends beyond dimensional accuracy. A part can be dimensionally perfect yet functionally useless if its metallurgical integrity has been compromised.

The Hidden Risk of Cross-Contamination

The corrosion resistance of stainless steel relies on a microscopic, chemically inert, chromium-oxide passive layer on its surface. This layer is fragile. Contact with free iron particles—from a carbon steel grinding wheel, a wire brush, or even a shared workbench—can implant contaminants that create sites for galvanic corrosion. This contamination is often invisible but can lead to premature, catastrophic product failure in the field.

We enforce a strict strategy of complete material segregation. Our stainless-dedicated space, tooling, and material handling equipment ensure its purity is guaranteed, preserving the corrosion resistance your design demands.

Ensuring Peak Performance Through Finishing

The final steps in fabrication are essential to protecting your investment and guaranteeing performance.

- Pickling and Passivation: Welding and other thermal processes can damage the passive layer. Finishing processes like pickling and passivation are not optional upgrades; they are mandatory final steps for critical applications.

- Our in-house passivation capability, compliant with ASTM A380, uses a chemical treatment to remove surface contaminants and free iron. This process chemically restores and enhances the passive layer, ensuring the component performs as specified in its service environment.

From Supplier to Partner: Redesigning for a Better Outcome

The highest form of partnership is one that actively improves your final product. Design for Manufacturability (DFM) is the collaborative process through which we serve not just as fabricators, but as expert manufacturing consultants. Many OEM engineering teams are masters of their product’s function but may be disconnected from the possibilities enabled by the latest fabrication technologies. Our role is to bridge that knowledge gap.

Our Collaborative DFM Process

Our approach is straightforward: first, we seek to understand the non-negotiable requirements of your component’s fit, form, and function. Then, we challenge the design to determine if we can achieve those goals more efficiently and effectively. This collaborative review often yields significant improvements in cost, quality, and performance.

DFM in Action:

- Weld Elimination: We frequently receive designs for multi-part assemblies with numerous welded seams. By leveraging the 660-ton forming capability of our Ermak CNC press brake, we can often redesign the assembly as a single, complex formed part. This eliminates costly, time-consuming welds while removing potential points of failure and distortion.

- Automation Enablement: For a high-volume component, a design may be functional but not optimized for automation. By strategically adjusting a feature or adding a locating tab, we can prepare the part for our five robotic welding cells, which dramatically improves consistency and lowers per-unit costs.

- Process Consolidation: It is common to see drawings that require secondary machining to achieve final tolerances. By utilizing our Prima Optimo 5-axis laser, we can often cut, bevel, and create critical features in a single operation, eliminating entire steps from the manufacturing process, reducing lead times, and improving overall accuracy.

The outcome is clear: you receive a component that is not only less expensive but is often higher quality, more robust, and more repeatable than the original design. This demonstrates a tangible return on investment for choosing a true partner over a simple order-taker.

Conclusion: Choose Certainty, Not Just a Fabricator

In today’s competitive environment, OEMs do not need another vendor to simply cut and bend metal. You need a strategic partner who can manage complexity, mitigate risk, and deliver manufacturing certainty—a partner whose processes are validated by an ISO 9001:2015 certification and whose technical claims are backed by over 70 years of experience.

Our “no tape measure” philosophy—powered by a fully integrated digital ecosystem and deep expertise in stainless steel—is how we deliver that certainty. We don’t just fabricate your design; we integrate with your team to ensure its ultimate success.

Note: Industry standards are subject to revision. Always consult the latest version for project-specific requirements. This guide is for informational purposes and does not constitute engineering advice.

Discuss Your Fabrication Challenge with Our Engineering Team

Partner with a fabricator that protects your investment. Submit your drawings to our team for a technical review and a comprehensive quote that reflects the true cost of quality.