Why You Need a

Stainless Steel Specialist as your

Fabrication Partner

Stainless steel resists corrosion because of an ultra-thin, self-healing chromium-oxide passive layer. It’s a powerful feature—and a fragile one. Excessive heat from improper welding, embedded iron from cross-contamination, and poor handling can damage that protective film and seed future failures. Our entire 160,000 sq. ft. facility, dedicated tooling, and documented workflow are engineered to preserve and restore that passive layer, ensuring your equipment performs for the long haul.

A Culture of Verifiable Quality:

ISO 9001, ASME IV & AWS

ISO 9001:2015

Our ISO 9001:2015 certified Quality Management System provides the framework for discipline and traceability. This system ensures that purchasing, receiving, work orders, inspection, and final documentation are in lockstep.

ASME & AWS

Our welding procedures and personnel are qualified in accordance with ASME Section IX and AWS standards, ensuring full compliance for critical applications like pressure vessels and process equipment. We deliver audit trails, not anecdotes.Material Integrity from Day One

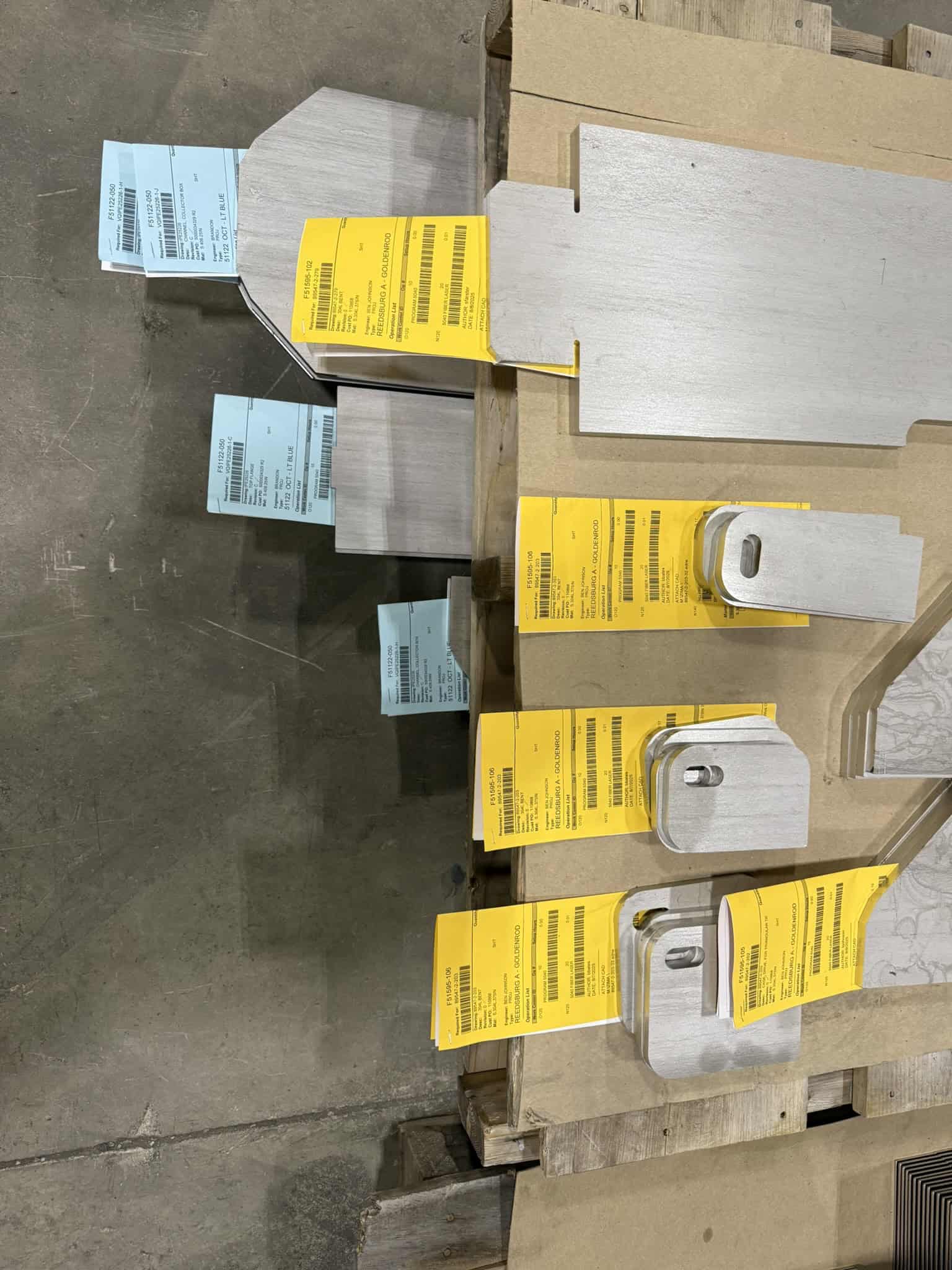

Mill Certs and Shop Floor Travelers

Every sheet, plate, tube, and fitting is linked through an inventory tag number to its Material Test Report (MTR) and heat number upon receipt. When the material is processed, that tag is associated with a specific traveler in our ERP system, and the traveler maintains that unique identity through cutting, forming, welding, finishing, and shipment.

Positive Material Identification (PMI) You Can Trust

While many fabricators rely solely on MTRs for materials, we know the supply chain includes both human error and outright fraud. That’s why we use X-Ray Fluorescence (XRF) for PMI. Besides use in standard procedures for receiving and auditing materials, we also can specify on your ITP to verify every critical component with our in-house Niton XRF analyzer.

Stainless Material Processing

We specialize in processing stainless steel—from common grades to high-nickel and duplex alloys—using clean handling, traceability, and tooling designed to preserve finish and integrity.

Processing Technologies

Contamination Control: A Stainless Specialist Mindset

Free iron is the enemy of stainless steel. Carbon steel particles embed in the surface, rust, and undercut the passive layer. We prevent this contamination with.

Dedicated Equipment

Stainless-only tools, including grinders, flap wheels, and stainless-bristle brushes.Segregated Work Areas

Dedicated stainless bays, protected benches, nylon slings, and coated forks to prevent contact with carbon steel.Atmospheric Control

Strict control of nearby grinding and cutting to stop airborne carbon steel dust from settling on stainless surfaces.Proof, Not Promises: Upon request, we can document ferroxyl or copper-sulfate screening of finished surfaces to provide verifiable proof of a free-iron-free surface.

Dedicated 40,000 SQFT Building for

Stainless Steel Fabrication

40,000 sq ft building engineered to protect stainless steel from cross-contamination and quality loss.

Why it matters: Cross-contamination is a critical risk in stainless steel fabrication—one that many job shops overlook. Our environment is built to protect finish quality, corrosion resistance, and compliance from the start. Whether you’re in pharma, food, water, or OEM systems, this level of discipline ensures your product performs—and passes inspection in critical stainless steel fabrications.

Master Craftsmen in Stainless Steel Fabrication

Our welders are masters of reducing heat input and eliminating distortion.

Weld automation improves weld quality and consistency.

Advanced robotic welding cells with tools tailored specifically for stainless steel fabrication.

World class fabricators and master craftsmen are experts in stainless steel fabrication.

Laser welding allows full penetration welds with low heat input, perfect for stainless steel fabrication projects.

Precision Cutting & Forming

Oxide-Free Laser Cutting

As a stainless steel specialist, we standardize on high-pressure nitrogen as the assist gas for stainless steel, which produces bright, oxide-free edges that are weld-ready. This eliminates the black scale that must be ground off, reduces the heat-affected zone (HAZ), and ensures tight-tolerance fit-up and corrosion resistance.

Advanced Press Brake Forming

Stainless steel springs back more than mild steel. Our expert operators and 6-axis CNC press brakes compensate with programmed over-bend and in-line automatic bend angle measurement. We also have tooling specifically chosen to be ideal for stainless steels.

Welding That Protects & Enhances Corrosion Resistance

A Process Portfolio Matched to the Job

TIG/GTAW: Used for thin, critical, or highly visible welds, delivering low heat input and top-tier aesthetics.

Pulsed MIG/GMAW-P: Provides higher productivity on thicker sections while precisely controlling heat input and eliminating spatter. We use argon-rich gas mixes tailored for stainless steel.

Robotic & Laser Welding: For high-volume repeatability and large assemblies, our robotic cells ensure consistency. For minimal distortion, our laser welding capabilities provide unparalleled precision.

Back-Purging as Standard Practice

We seal and purge the root side of welds with argon gas to prevent oxidation (“sugaring”), preserving corrosion resistance inside tanks, pipe spools, and enclosed chambers. Where specified, we verify purge quality with a digital oxygen analyzer to ensure perfection.

Correct Filler Metal, Every Time

Our AWS-certified welders follow exact procedures: 304L is welded with 308L, 316L with 316L, and dissimilar transitions (e.g., stainless to carbon) with 309L. This is documented and verified, ensuring the final weldment meets or exceeds the corrosion performance of the parent material.

Distortion Control by Design

Our process begins with precision-cut parts that ensure excellent fit-up. We then employ strategic tacking plans, balanced welding sequences, strict heat-input limits, and robust fixturing to keep components straight and dimensions true through the entire fabrication process.

Finishing That Restores the Protective Passive Layer

Mechanical & Chemical Cleaning

Post-weld, we use dedicated stainless-only brushes to remove heat tint. For more demanding applications, we perform pickling using a controlled HF/HNO₃ process to remove the chromium-depleted layer, bringing the surface back to its fully alloyed state.

Final Passivation to ASTM Standards

We perform final passivation in accordance with ASTM A380/A967 standards. We use either nitric or citric acid processes to dissolve any residual free iron and promote a uniform, corrosion-resistant chromium-oxide film. Citric options are available for food-adjacent environments. Upon request, verification tests (water-break, copper-sulfate, or ferroxyl) can be included in your final documentation package.

Metrology, Documentation & Deliverables

3D-to-Shop Integration: We program directly from your 3D models, ensuring design intent is maintained from cutting and forming through final inspection.

Advanced Inspection: Our Leica AT960 laser tracker enables rapid, high-precision dimensional checks and as-built verification against your model.

Comprehensive Quality Records: We can deliver a complete data package, including MTRs, PMI logs, weld maps, passivation certifications, and final inspection reports—organized and delivered with your shipment.

Industries We Serve

Water & Wastewater: Clarifiers, troughs, baffles, covers, aeration piping, skids, and frames.

Power, Energy & Chemical: Ducting, scrubber internals, dampers, support structures, tanks, and chutes.

Food & Beverage (Non-Sanitary): Structural frames, conveyors, guards, and enclosures finished for maximum corrosion resistance.

Pulp & Paper / Mining: Chutes, hoods, platforms, and washdown-rated equipment.

Your Plant Visit Checklist: What to Look For

When you visit our facility, you will see verifiable proof of our commitment:

- Segregated stainless bays, dedicated tooling, and protected material handling paths.

- A robust PMI program that uses XRF for on-site PMI.

- Lasers running nitrogen for clean, oxide-free edges.

- Press brakes and tooling configured to master springback and prevent galling.

- Documented ASME & AWS certified welding procedures in active use.

- A systematic process for weld cleaning, pickling, and passivation.

- ISO 9001 documentation driving every step, from order entry to final inspection report.

Ready work with a Stainless Specialist?

end your drawings and project requirements. Our engineering team will provide a comprehensive technical review and a detailed proposal backed by our ASME and ISO 9001 certified processes. Let’s build it right, together.

Who We Build For

With over 74 years of stainless steel fabrication experience, Northern is trusted by engineers, OEMs, and procurement teams across a wide range of stainless-intensive industries.

Water and Wastewater Treatment

Fabrication for clarifiers, skimmers, tanks, and flow control systems—built to resist corrosion in harsh, wet environments.

Food Processing

Sanitary weldments and high-finish assemblies for USDA-regulated applications, made to pass inspections and perform in washdown zones.

Industrial Equipment & Machinery

Custom stainless enclosures, frames, hoppers, and skids for heavy-duty equipment manufacturers.

Construction & Infrastructure

Structural stainless steel, platforms, supports, and project-specific metal components.

High Heat Applications-

Ovens, Furnaces, Glass

Specialty alloys for elevated temperature exposure—317, 321, 347

Air Filtration and

Pollution Control

Large-scale ductwork, stacks, and housings for scrubber and air handling systems.

Pulp, Paper &

Recycling Equipment

Heavy-gauge stainless weldments for rugged, high-moisture processing environments.

Architectural and

Structural Stainless

Visible stainless work with high visual and structural requirements—precision formed, cleanly welded.

Power and Process Piping

Pipe spools, skids, and tank assemblies fabricated to ASME spec with CWI oversight and traceability.