Beyond the Cut: How Advanced Fabrication Preserves the Value and Integrity of Stainless Steel Components

Specifying stainless steel for a component is an investment in longevity, performance, and corrosion resistance. However, these inherent material properties can be unknowingly compromised or destroyed during fabrication. The choice of a CNC cutting process is not a trivial detail; it is a critical engineering decision that directly impacts metallurgical integrity, downstream production costs, and long-term reliability. An improper cut, often chosen for a deceptively low “cost per inch,” can introduce thermal damage that necessitates costly rework and creates a latent risk for premature field failure and warranty claims. This paper establishes why Northern Manufacturing’s fabrication strategy—built on a foundation of

high-power, precision fiber laser cutting with a pure nitrogen assist gas—is the most effective method for preserving the integrity of stainless steel, delivering the lowest true cost per part and ensuring the component’s performance matches the material’s promise.

Introduction: The High Cost of an Improper Cut

You invested in stainless steel for a reason. Whether for sanitary compliance, performance in a corrosive environment, or superior strength, the material was chosen to ensure reliability. The assumption is that these properties carry through to the final component. However, a significant and often overlooked risk lies in the fabrication process itself. An improper cutting method can deliver a part that is dimensionally accurate but metallurgically flawed.

The consequences of such a flaw range from immediate financial penalties to long-term brand damage. An ugly, oxidized cut edge can be rejected outright by a quality-conscious customer. A thermally damaged edge can compromise weld quality, leading to rework. Most insidiously, microscopic damage below the surface can create a pathway for corrosion, leading to premature product failure long after it has left the factory. This is the ultimate risk: a component that fails to deliver the longevity and corrosion resistance that were the entire justification for its material specification.

The Problem Statement: Deconstructing the True Cost Per Part

In a competitive market, it is tempting to select a fabrication partner based on the lowest quoted cost per inch or cost per part. This metric, however, is dangerously misleading. It often conceals the significant hidden costs and risks associated with inferior thermal cutting processes. The true cost of a fabricated part is a function of not only the initial cut but also the mandatory secondary operations and the potential for future failure.

The primary culprit is the Heat Affected Zone (HAZ). All thermal cutting processes create a HAZ, an area adjacent to the cut where the material was not melted but was heated enough to alter its microstructure. In stainless steel, this leads to a critical failure mechanism known as sensitization. When the material is heated to between 450°C and 850°C, chromium and carbon combine at the grain boundaries. This process depletes the surrounding area of the chromium required to form the passive, corrosion-resistant oxide layer. If the chromium level drops below 10.5%, the steel loses its “stainless” property in that zone, making it highly susceptible to intergranular corrosion.

A fabrication quote that relies on a process creating a large HAZ may seem inexpensive, but it forces you to incur other costs:

- Mandatory Rework: The dark, oxidized scale on a poorly cut edge must be mechanically ground off before welding to ensure quality. This manual labor adds significant time and cost not reflected in the initial quote.

- Warranty & Rework Costs: If a compromised edge is not properly treated, it becomes the weak point of the entire assembly. When corrosion begins at the cut edge, it can lead to warranty claims, field repairs, and product recalls, directly impacting your bottom line and reputation.

The Superior Solution: Northern Manufacturing’s High-Power Fiber Laser with Nitrogen Shielding

At Northern Manufacturing, our fabrication philosophy is built on a strategic investment in the technology that best mitigates these risks: high-power fiber laser cutting. This is not simply one option among many; it is our standardized approach for delivering the optimal balance of quality, speed, and cost-effectiveness for stainless steel.

Speed & Efficiency = Lower Part Costs

While the hourly operating cost of a high-power laser system is high, its productivity is unmatched. Our 12,000-watt Trumpf Fiber Laser is incredibly efficient at cutting stainless steel across a wide range of thicknesses up to 1.5 inches. On materials under 8mm, a fiber laser can be three to four times faster than other methods. When combined with automated material loading and part unloading systems, the throughput is maximized, dramatically reducing the time required per part. This extreme productivity means that even with a higher machine rate, the final cost per part is consistently lower than that of slower, less efficient processes.

The Critical Role of Nitrogen Shielding

The single most important process parameter for laser cutting stainless steel is the choice of assist gas. While some shops may be tempted to use cheaper shop air or oxygen to reduce costs, this is a critical error that introduces oxidation. We have standardized on high-purity, high-pressure nitrogen for one reason: to guarantee material integrity.

Nitrogen is an inert gas; its sole purpose is to physically eject the molten metal from the cut path without reacting with the hot edge. This non-reactive process delivers two crucial benefits:

- Guaranteed Corrosion Resistance: By shielding the hot edge from atmospheric oxygen, nitrogen cutting prevents the formation of any oxide scale. This leaves the material’s chromium free to form its protective passive layer, preserving 100% of the inherent corrosion resistance right up to the edge of the cut.

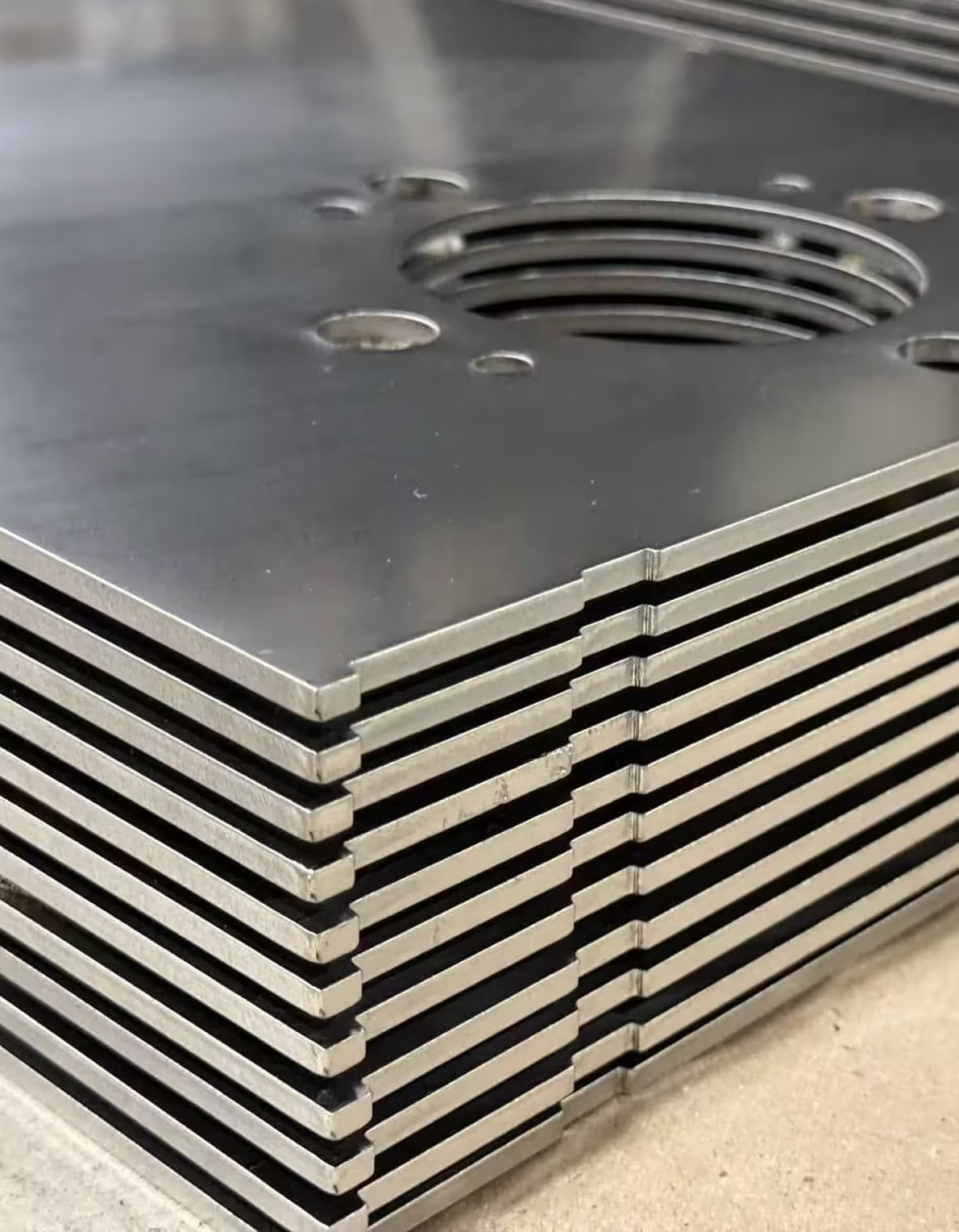

- Finished, Weld-Ready Edges: The resulting cut edge is bright, clean, and silver. Parts come off the machine ready for the next step. Welded edges require no pre-cleaning, and non-welded edges are aesthetically perfect and require no secondary finishing, saving time and labor costs.

Minimal HAZ, Maximum Integrity

Due to the extremely high energy density of the focused laser beam and the rapid cutting speeds, the total heat input into the material is minimized. This results in the smallest possible HAZ of any thermal cutting method. This minimal thermal impact effectively eliminates the risk of sensitization, ensuring the material’s microstructure remains unchanged and its performance uncompromised.

An Educational Overview of Alternative Cutting Methods

While we standardize on fiber laser, a comprehensive understanding of all processes is key to making informed engineering decisions. Other technologies exist, but they involve significant trade-offs in quality, speed, or cost that we find unacceptable for the precision stainless steel components our clients require.

- High-Definition Plasma: For very thick stainless steel plate (typically >1 inch), HD plasma can offer a speed advantage. However, it produces a much more significant HAZ and requires deep process expertise and premium gas blends to produce even a marginally acceptable edge. This introduces thermal risk and often requires significant post-processing, negating the initial speed benefit.

- Abrasive Waterjet: This is a non-thermal, cold-cutting process used for specialty applications where absolutely no HAZ is permissible or for cutting materials that cannot be processed by laser. While it imparts no heat, its use is limited by significant drawbacks: a very high cost per part, extremely slow cutting speeds, and the potential for undesirable edge taper in thick materials. It is a niche tool, not a workhorse for a precision fabrication environment.

- Incompatible Processes (Oxy-Fuel): It is critical to note that oxy-acetylene or flame cutting is fundamentally incompatible with stainless steel. The process relies on the rapid oxidation of iron, a reaction which is prevented by the material’s high chromium content. Any attempt to use this method results in uncontrolled melting and a destroyed, unusable part.

Conclusion: A Strategic Partnership for Stainless Steel Fabrication

The decision of how to cut a stainless steel part is as critical as the decision to use stainless steel in the first place. A focus on a superficial “cost per inch” can easily lead to a partnership that introduces unacceptable risks, hidden costs, and the potential for long-term product failure.

Northern Manufacturing’s strategic standardization on high-power fiber laser technology with pure nitrogen shielding is a deliberate business decision. It is our commitment to providing our customers with the lowest true part cost, the fastest possible delivery, and, most importantly, the uncompromising material integrity that their applications demand. We are an ISO 9001:2015 certified partner, with a legacy of quality dating back to 1951. We don’t just cut parts; we deliver certainty.

Discuss Your Fabrication Challenge with Our Engineering Team

Partner with a fabricator that protects your investment. Submit your drawings to our team for a technical review and a comprehensive quote that reflects the true cost of quality.