The Problem with Unrealistic Metal Fabrication Tolerances

Introduction: A Strategic Framework for Stainless Steel Fabrication

Sourcing custom stainless steel fabrications is a complex undertaking that extends far beyond a simple transaction. It is a strategic process that demands a sophisticated understanding of the interplay between engineering design, material science, and manufacturing economics. For Original Equipment Manufacturers (OEMs), success hinges on the ability to navigate these complexities effectively, ensuring that every component not only meets its functional requirements but also contributes to a cost-effective and reliable final product. A poorly defined specification can lead to a cascade of negative outcomes, including production delays, assembly failures, budget overruns, and compromised quality. Its critical that fabrication tolerances are clearly defined and realistic to ensure projects are successful.

This guide is designed to provide a strategic framework for the key stakeholders within an OEM who are integral to this process. It directly acknowledges and addresses their distinct yet interconnected priorities:

- The Engineer’s Perspective: The primary focus for engineers is the translation of design intent into a physical part that performs flawlessly. This involves achieving precise dimensions, ensuring functional integrity, and managing the unique and often challenging material properties of stainless steel, from its inherent strength to its behavior under the thermal stress of welding.

- The Quality Manager’s Perspective: For quality managers, the objective is absolute certainty. They are tasked with ensuring that every fabricated part is dimensionally correct, conforms to all relevant standards, and is produced with a high degree of repeatable consistency. Their work is critical to minimizing defects, eliminating costly rework, and upholding the reputation of the final product in the marketplace.

- The Purchasing Manager’s Perspective: The purchasing manager’s role has evolved from securing the lowest per-part price to achieving the best Total Cost of Ownership (TCO). This holistic view encompasses not only the initial procurement cost but also the downstream costs associated with scrap, inspection, assembly challenges, and the inherent risks tied to a supplier’s capabilities.

The cornerstone of a successful and efficient OEM-fabricator partnership is a well-defined specification, one that is grounded in a shared, unambiguous understanding of tolerances and international standards. This document serves as a comprehensive roadmap for navigating the critical decisions involved in creating such a specification. It provides the technical depth required by engineers, the procedural clarity needed by quality managers, and the strategic economic insights essential for purchasing managers to make informed, value-driven decisions.

Section 1: The Language of Precision: Understanding Tolerances in Stainless Steel

At the heart of every manufacturing drawing is the concept of tolerance. It is the technical language used to define acceptable variation, and a fluent understanding of its principles is non-negotiable for anyone involved in specifying or procuring fabricated parts.

1.1 Defining Manufacturing Tolerance

In manufacturing, it is physically and economically impossible to produce a part to an exact, perfect dimension. Every process, from cutting to bending, introduces a small degree of variation. Manufacturing tolerance is the total permissible amount a specific dimension may vary from its nominal (or ideal) value. It is expressed as the difference between the upper (maximum) and lower (minimum) limits of a dimension. For example, a dimension specified as

25mm±0.2mm has a nominal size of 25 mm, an upper limit of 25.2 mm, a lower limit of 24.8 mm, and a total tolerance zone of 0.4 mm.

Tolerances are not arbitrary; they are fundamental to a product’s functionality. They control the fit and function of mating parts in an assembly, ensuring that components produced separately will assemble correctly and perform as intended. This principle, known as

interchangeable parts, is the foundation of modern mass production, allowing for efficient assembly and the replacement of individual components without custom fitting.

1.2 The Stainless Steel Baseline

The choice of material has a profound impact on the achievable tolerances in fabrication. Stainless steel, particularly the common austenitic grades like 304 and 316, possesses a unique combination of properties that sets it apart from other common metals. Due to its high strength and lower malleability, stainless steel inherently requires and supports tighter tolerances than more ductile materials.

A comparison of typical tolerance ranges for sheet metal fabrication illustrates this point clearly:

- Stainless Steel (e.g., 304): ±0.005′′ to ±0.015′′ (approx. ±0.13mm to ±0.38mm)

- Aluminum (e.g., 6061-T6): ±0.010′′ to ±0.030′′ (approx. ±0.25mm to ±0.76mm)

- Mild Steel (e.g., 1018): ±0.015′′ to ±0.045′′ (approx. ±0.38mm to ±1.14mm).

This higher precision is a direct result of stainless steel’s material properties. Its greater strength means it resists deformation during processing, allowing for more accurate cuts and forms. However, this same property makes it less forgiving; it does not “move” or yield as easily as aluminum, meaning that initial process accuracy is paramount.

1.3 Process-Specific Tolerances

Each step in the fabrication workflow has its own set of achievable tolerances. Engineers must design with these specific process capabilities in mind to create a part that is both functional and manufacturable.

- Laser Cutting: As a high-precision thermal cutting process, laser cutting offers some of the tightest tolerances in primary fabrication. It is common to achieve linear dimensional tolerances of ±0.1mm (approx. ±0.005′′) on parts up to 1000 mm in length. For smaller parts or critical features like small holes, this can be tightened to as low as ±0.05mm (approx. ±0.002′′).

- Bending/Forming: The process of bending introduces more variables than cutting. Angular tolerances are typically held to ±0.5∘. The resulting linear dimensions of the bent features are influenced by material thickness, tooling, and the inherent phenomenon of springback, where the material partially returns to its original shape after the bending force is removed. This results in typical linear tolerances for bent features ranging from ±0.3mm to ±0.8mm.

- Welding: Welding introduces intense, localized heat, making it the process with the widest potential tolerance range. The thermal expansion and contraction of the material during welding inevitably leads to distortion. Consequently, linear dimensional tolerances for welded assemblies typically range from ±0.5mm to ±2.0mm, with angularity varying by as much as ±2∘. Managing these wider tolerances is a primary focus of weldment design and is governed by specific standards, as discussed in Section 2.

- Stamping: For high-volume production, stamping uses dies to form parts with excellent repeatability. This process can achieve tight tolerances, typically in the range of ±0.1mm to ±0.5mm. For critical features, stamping can achieve tolerances as tight as ±0.05mm.

1.4 The Tolerance Chain: From Raw Material to Finished Part

An often-overlooked factor in achieving final part precision is that the tolerance of a finished fabrication is a cumulative result—a “stack-up” of variations that begins with the raw material itself. A specification calling for a tight final tolerance cannot be cost-effectively met if the starting material already possesses a wide dimensional variance. This creates a critical link between raw material selection, a key purchasing decision, and the feasibility of subsequent manufacturing operations.

Consider the standard tolerances for stainless steel bar stock:

- Hot-Rolled Bar: This material is formed at high temperatures and has a looser tolerance. For example, a 1.5-inch to 2-inch diameter bar may have a tolerance of +1/64′′ (approx. +0.0156′′) and no negative tolerance.

- Cold-Finished Bar: This material is drawn or rolled at room temperature, resulting in a smoother finish and much tighter dimensional control. A 0.5-inch to 1-inch diameter bar can have a tolerance of ±0.002′′.

Similarly, stainless steel tubing tolerances vary significantly based on the manufacturing method (e.g., seamless vs. welded) and finishing process (hot-finished vs. cold-finished). An engineer specifying a feature tolerance of

±0.005′′ on a part to be made from hot-rolled stock is creating an immediate manufacturing challenge. The fabricator must first machine the oversized raw material down to a state where the final feature can be accurately produced, adding significant cost and time. Conversely, specifying more expensive cold-finished stock from the outset may result in a lower total cost by eliminating these secondary operations. This demonstrates how a seemingly simple purchasing decision on raw material directly enables or complicates the entire manufacturing workflow.

The following table provides a summary of typical tolerances for the primary stainless steel fabrication processes, which should serve as a baseline for design and specification.

| Process | Typical Tolerance Range | Key Influencing Factors |

| Laser Cutting | Linear: ±0.1mm (±0.005′′) Holes: ±0.05mm (±0.002′′) | Material thickness, machine calibration, assist gas type and pressure, heat-affected zone (HAZ) |

| Bending / Forming | Angular: ±0.5∘ Linear: ±0.3mm to ±0.8mm | Material springback, V-die width, tooling quality and wear, bend radius consistency |

| Welding | Linear: ±0.5mm to ±2.0mm Angular: ±2∘ | Heat input, weld sequencing, joint design, fixturing, material properties (thermal expansion/conductivity) |

| Stamping | Linear: ±0.1mm to ±0.5mm Critical Features: ±0.05mm | Die design and precision, material properties (ductility, grain direction), press speed and force, lubrication |

Section 2: A Deep Dive into International Standards for Fabrication

While tolerances define the acceptable limits of variation, standards provide the framework for communicating these requirements clearly and consistently. Adhering to internationally recognized standards is a strategic decision that elevates a technical drawing from a mere diagram to a precise, unambiguous, and legally enforceable contract between the OEM and the fabricator.

2.1 Communicating Intent: Title Block Tolerances vs. ISO Standards

There are two primary methods for specifying general tolerances on an engineering drawing, each with significant implications for clarity and cost.

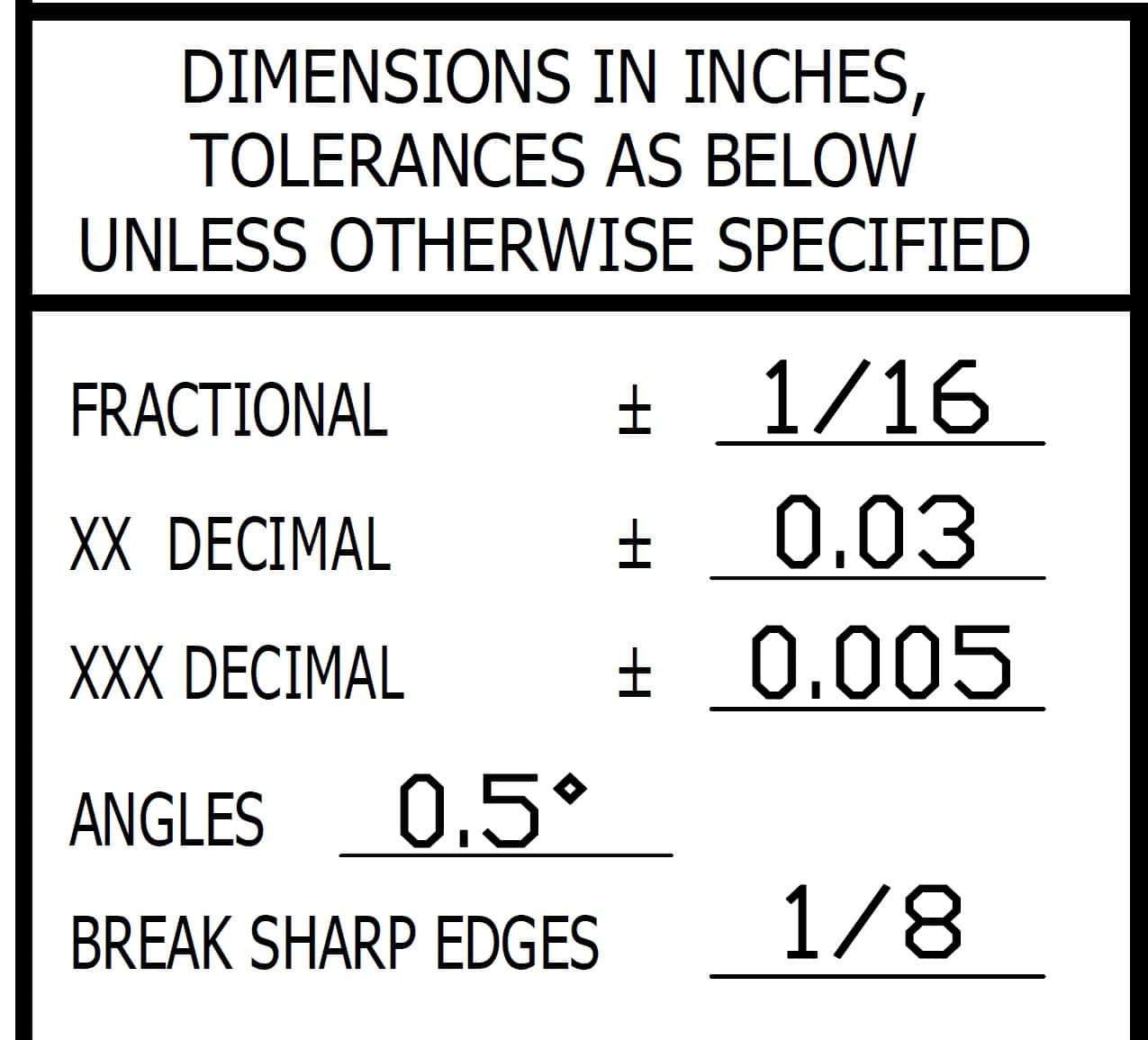

- Title Block Tolerances: A common practice, particularly in North America, is to define general tolerances in the drawing’s title block based on the number of decimal places used for a dimension. For example, a title block might state:

- X.X=±0.5mm

- X.XX=±0.1mm

- X.XXX=±0.05mm.

This method automatically assigns a tolerance based on how the engineer dimensions the part. While seemingly simple, this approach is fraught with potential issues. It can lead to ambiguity, especially in a global supply chain where metric drawings are standard and the practice of dropping trailing zeros can inadvertently change a feature’s required precision. More critically, it often encourages designers to default to a certain number of decimal places out of habit, inadvertently applying unnecessarily tight tolerances to non-critical features, which can dramatically and needlessly increase manufacturing costs.

- ISO Standards: The International Organization for Standardization (ISO) develops and publishes standards that provide a shared, universal technical language for industries worldwide. Adopting ISO standards for tolerancing is a strategic move to eliminate ambiguity, reduce misinterpretation, and streamline communication with suppliers, regardless of their geographic location. When a drawing references a specific ISO standard, it invokes a comprehensive and globally understood set of rules for dimensional and geometric accuracy.

2.2 ISO 2768: The Global Standard for Machined and Formed Features

ISO 2768 is a foundational standard that provides general tolerances for parts produced by material removal (machining) or forming from sheet metal. Its purpose is to simplify drawings by establishing default tolerances for any dimension not given a specific, individual tolerance. The standard is divided into two parts:

- ISO 2768-1: General Tolerances for Linear and Angular Dimensions. This part defines four tolerance classes that dictate the level of precision:

- F (fine)

- M (medium)

- C (coarse)

- V (very coarse). The “medium” class is the most commonly specified for general fabrication and sheet metal work.

- ISO 2768-2: Geometrical Tolerances for Features. This part governs the form of a part, covering characteristics like straightness, flatness, perpendicularity, symmetry, and run-out. It specifies three precision classes:

- H (high precision)

- K (medium precision)

- L (low precision).

On an engineering drawing, the standard is called out by combining the desired classes from each part. For example, ISO 2768-mK is a very common specification for sheet metal components. This single note tells the fabricator that all unspecified linear and angular dimensions must adhere to the “medium” class from Part 1, and all unspecified geometric features must meet the “K” class from Part 2.

ISO 2768-m (Medium) Tolerances for Linear Dimensions

| Basic Size Range (mm) | Permissible Deviation (mm) |

| 0.5 up to 3 | ±0.1 |

| over 3 up to 6 | ±0.1 |

| over 6 up to 30 | ±0.2 |

| over 30 up to 120 | ±0.3 |

| over 120 up to 400 | ±0.5 |

| over 400 up to 1000 | ±0.8 |

| over 1000 up to 2000 | ±1.2 |

| over 2000 up to 4000 | ±2.0 |

2.3 ISO 13920: The Essential Standard for Welded Assemblies

While ISO 2768 is excellent for features created by mechanical means, it is not designed to account for the significant thermal distortion inherent in welding. For this, a separate standard is required: ISO 13920: General Tolerances for Welded Constructions. This standard is specifically intended to govern the overall dimensional and geometric accuracy of a completed weldment or welded assembly. It acknowledges the realities of heat-induced movement and provides a realistic framework for workshop accuracy.

Like ISO 2768, ISO 13920 is divided into classes:

- Tolerance Classes for Linear and Angular Dimensions: Four classes, A, B, C and D, with A being the finest and D being the most coarse.

- Tolerance Classes for Geometrical Form (Straightness, Flatness, and Parallelism): Four classes, E, F, G, and H with E being the most precise.

A common specification for a welded assembly requiring good functional accuracy would be ISO 13920-BE. This indicates that linear dimensions should meet Class B and geometric form should meet Class E. According to the standard, any manufacturing documentation for a welded part that lacks a reference to general tolerances is considered incomplete.

It is crucial to recognize that these two standards, ISO 2768 and ISO 13920, are not interchangeable; they govern different physical processes. Many complex stainless steel fabrications, such as a welded chassis that subsequently has mounting holes machined into it, require the application of both standards on the same drawing. In such a case, the overall straightness and flatness of the welded frame should be governed by ISO 13920, while the size and location of the precision-machined holes should be governed by ISO 2768. Specifying only ISO 2768 for the entire part would impose an unrealistic and often unachievable standard on the welded structure, leading to disputes and rejections. Conversely, specifying only ISO 13920 would not provide sufficient control for the critical machined features. A well-constructed drawing will clearly delineate which standard applies to which features, eliminating ambiguity for the fabricator and the quality inspector.

ISO 13920-B and ISO 13920-E Tolerances for Welded Assemblies

| Nominal Size Range (l) in mm | Class B: Linear Tolerance (t) in mm | Class E: Straightness/Flatness Tolerance (t) in mm |

| 30 < l ≤ 120 | ±2 | 0.5 |

| 120 < l ≤ 400 | ±3 | 1.0 |

| 400 < l ≤ 1000 | ±4 | 1.5 |

| 1000 < l ≤ 2000 | ±6 | 2.0 |

| 2000 < l ≤ 4000 | ±8 | 3.0 |

| 4000 < l ≤ 8000 | ±10 | 4.0 |

2.4 The Quality Manager’s Advantage: How Standards Drive Consistency and Reduce Risk

For a Quality Manager, the adoption of ISO standards is not merely a matter of good practice; it is the bedrock of an effective and defensible Quality Management System (QMS), such as one certified to ISO 9001. Standards provide a clear, objective, and universally understood language that transforms quality control from a subjective art into a repeatable science.

- Reducing Ambiguity and Streamlining Inspection: When a drawing specifies “ISO 13920-BE,” it removes all guesswork from the inspection process. The pass/fail criteria for every dimension and feature are explicitly defined in the standard’s tables. This eliminates debates over interpretation between the OEM’s inspector and the supplier’s quality team. Inspection becomes a straightforward process of measurement against a clear, authoritative benchmark.

- Minimizing Scrap and Rework: By providing the manufacturing team with a clear and achievable target, standards significantly reduce the likelihood of errors and non-conforming parts. This directly translates into lower scrap rates and a reduction in the costly and time-consuming cycles of rework and repair.

- Ensuring Supplier Accountability: A purchase order and drawing that reference a specific ISO standard form a clear contractual agreement. If a supplier delivers parts that fall outside the specified tolerance class, the OEM has a clear, objective, and legally defensible basis for rejecting the shipment. This holds suppliers accountable for the quality they produce and protects the OEM from accepting substandard components. Ultimately, standards create a framework for consistency that benefits the entire supply chain, leading to higher quality products, improved efficiency, and stronger, more transparent partnerships.

Section 3: The Heat Challenge: Mastering Distortion in Stainless Steel Welding

Welding is a process of controlled violence, subjecting metal to extreme thermal cycles that fundamentally alter its state. While all metals are affected, austenitic stainless steels are uniquely susceptible to distortion, or warping, during welding. Understanding the material science behind this phenomenon is essential for designing weldments that can be manufactured to specification.

3.1 The Physics of Weld Distortion

All conventional arc welding processes create distortion. The intense, localized heat from the arc causes the metal in the weld zone to expand rapidly. The surrounding cooler base metal restrains this expansion, creating compressive stresses that can cause the hot, softened weld metal to plastically deform. As the weld cools and contracts, it is now effectively shorter than it was in its original state. This shrinkage creates powerful tensile forces that pull on the surrounding material, causing the entire assembly to bend, twist, or warp. These locked-in forces are known as residual stresses. If these stresses exceed the material’s ability to resist them, the part will distort.

3.2 Why Stainless Steel Warps More

Austenitic stainless steels, such as grades 304 and 316, distort significantly more during welding than common carbon steels. This behavior is not due to poor technique but is a direct consequence of two key physical properties that differ dramatically between the two materials.

- Higher Coefficient of Thermal Expansion (CTE): This property measures how much a material expands for each degree of temperature increase. Austenitic stainless steel has a CTE that is approximately 50% higher than that of carbon steel. This means that for the same amount of heat input, stainless steel will expand more when heated and, more importantly, contract more as it cools. This greater shrinkage generates substantially higher tensile forces, making it far more likely to pull the assembly out of its intended shape.

- Lower Thermal Conductivity: This property measures how efficiently a material conducts heat. Stainless steel is a notoriously poor conductor of heat, with a thermal conductivity only about one-third that of carbon steel. When welding, this low conductivity prevents heat from dissipating quickly from the weld zone into the rest of the part. Instead, the heat becomes highly concentrated, creating a very steep temperature gradient between the molten weld puddle and the adjacent base metal. This extreme, localized heating and cooling cycle exacerbates the expansion and contraction effects, leading to more severe and less predictable distortion.

It is a fundamental reality of material science that the very element responsible for stainless steel’s primary benefit—chromium—is also a contributor to its primary fabrication challenge. The high chromium content is what allows stainless steel to form its passive, corrosion-resistant chromium oxide layer. However, increasing the chromium content in a steel alloy also significantly reduces its thermal conductivity. Therefore, the property that makes the material desirable (corrosion resistance) is causally linked to the property that makes it difficult to weld without distortion (low thermal conductivity). This represents a core trade-off that engineers must manage through intelligent design.

3.3 Comparing Common Grades: 304 vs. 316

A common point of inquiry is whether grade 316 stainless steel behaves differently from grade 304 during welding. Grade 316 contains molybdenum, which significantly enhances its resistance to pitting and crevice corrosion, especially in chloride-rich environments like marine or chemical processing applications. However, from a thermal perspective, the two grades are nearly identical. Their coefficients of thermal expansion and thermal conductivity values are so similar that, for the purposes of predicting and managing weld distortion, they can be treated as having the same challenging behavior. The decision to specify 316 over 304 should be based entirely on the service environment’s corrosion demands, not on any perceived difference in weldability or distortion characteristics.

The table below quantifies the critical differences in thermal properties that drive distortion behavior.

Comparative Thermal Properties of Austenitic Stainless Steel vs. Carbon Steel

| Material | Mean Coefficient of Thermal Expansion (CTE) (10−6/K between 20∘C and 300∘C) | Thermal Conductivity (W/m⋅K at room temp.) |

| 304 Stainless Steel | 17.0 | 16.2 |

| 316 Stainless Steel | 17.0 | 16.3 |

| Carbon Steel | ~11.0 – 12.0 | ~45.0 – 52.0 |

3.4 Mitigation Strategies: A Collaborative Approach

While distortion cannot be eliminated entirely, it can be effectively managed through a combination of intelligent design and disciplined fabrication practices.

- For the Engineer (Design Phase): The battle against distortion begins on the drawing board.

- Minimize Weld Volume: Specify joint designs that require the least amount of filler metal. For example, a double-V groove joint requires significantly less weld metal than a single-V joint for the same plate thickness, resulting in less overall shrinkage.

- Balance Welds: Whenever possible, place welds symmetrically around the part’s neutral axis. This allows the shrinkage forces from one weld to counteract the forces from another, minimizing angular distortion.

- Strategic Weld Placement: Locate welds away from critical features and in areas where some distortion is acceptable.

- For the Fabricator (Execution Phase): Skilled fabricators employ a range of techniques to control heat and restrain the material.

- Robust Fixturing: Using rigid clamps, braces, and fixtures to hold the parts firmly in place during welding can physically prevent much of the movement. It is critical that these fixtures be made of stainless steel to avoid iron contamination.

- Tack Welding: Placing small tack welds along the joint before final welding helps to hold the alignment. For stainless steel, these tacks should be placed at roughly half the spacing used for carbon steel due to the higher shrinkage forces.

- Heat Input Control: The goal is to make the weld with the minimum amount of heat necessary. This is achieved by using the lowest practical amperage settings (often 10-15% less than for carbon steel), maintaining a consistent and fast travel speed, and using stringer beads rather than wide weaving motions.

- Weld Sequencing: Implementing a planned welding sequence (e.g., backstep welding, skip welding) can help distribute the heat and stress more evenly across the fabrication, preventing the accumulation of stress in one area.

Managing weld distortion is a collaborative effort. An engineer who understands these principles can design a part that is inherently less prone to warping, making it easier and more cost-effective for a skilled fabricator to produce a high-quality, dimensionally accurate component.

Section 4: The Cost of Precision: A Strategic Guide to Tolerance Specification

In manufacturing, precision comes at a price. One of the most common and costly mistakes in product development is the specification of unnecessarily tight tolerances. The relationship between the tightness of a tolerance and its associated manufacturing cost is not linear; it is exponential. A clear understanding of this relationship is essential for engineers to design for manufacturability and for purchasing managers to achieve the best total cost of ownership.

4.1 The Exponential Cost of Tight Tolerances

As tolerances become tighter, the cost to achieve them increases dramatically. This is because each incremental improvement in precision requires more advanced machinery, higher-quality tooling, longer cycle times, more skilled labor, and more sophisticated inspection methods.

Data from multiple studies illustrates this stark reality. A classic analysis shows that if rough machining to a tolerance of ±0.030′′ has a relative cost of 1x, tightening that tolerance to ±0.005′′ doubles the cost to 2x. Further tightening to ±0.001′′ doubles the cost again to 4x. Achieving a very high-precision tolerance of ±0.0001′′ can increase the cost by a factor of 24 or more. While modern CNC technology has made precision more accessible, the shape of this exponential cost curve remains unchanged. Moving from a still-tight tolerance of ±0.001′′ to a high-precision ±0.00025′′ can still quadruple the cost of that specific feature.

4.2 Identifying the “Cost Cliffs”: When a Thousandth of an Inch Doubles the Price

The exponential cost increase is not a smooth curve but is better understood as a series of “cost cliffs.” These are specific tolerance thresholds where the manufacturing process must fundamentally change to a more complex and expensive method to achieve the required accuracy. Crossing one of these thresholds can dramatically increase the cost of a feature.

- Example 1: Fabricating Holes:

- Standard Tolerance (±0.5mm): Can be quickly and cheaply produced with a single operation like laser cutting or punching.

- Tighter Tolerance (±0.1mm): May require a secondary operation, such as drilling or reaming after the initial hole is made, adding a process step and increasing cost by 40-60%.

- Precision Tolerance (±0.01mm): This level of accuracy is often beyond the capability of drilling. It necessitates moving the part to a CNC milling machine and using a precision boring head. This involves a more expensive machine, a tool change, and a much slower machining time, easily increasing the feature’s cost by 4 to 5 times.

- Example 2: Achieving Flatness:

- Standard Tolerance (per ISO 13920): Can typically be achieved through skilled welding and fixturing alone.

- Tighter Tolerance: If a weldment requires a flatness that is tighter than the welding standard allows, it will require post-fabrication operations. This could involve mechanical straightening in a press or, for higher precision, moving the entire weldment to a large milling machine or grinder to machine the surfaces flat, adding enormous cost and lead time.

- Example 3: The Cost of Inspection:

- Standard Tolerance (±0.5mm): Can be quickly and easily verified on the shop floor using standard tools like calipers or tape measures.

- Precision Tolerance (±0.05mm): This level of precision may exceed the reliability of hand tools. Verification requires a temperature-controlled quality lab and a Coordinate Measuring Machine (CMM), a highly sophisticated and expensive piece of equipment that requires a skilled operator and significant programming and inspection time, adding substantial overhead to the part cost.

4.3 Design for Manufacturability (DFM): The Engineer’s Role in Cost Control

The engineer is the primary driver of a part’s cost, as their decisions on the drawing dictate the required manufacturing processes. Adopting Design for Manufacturability (DFM) principles for tolerancing is the most effective way to control costs without sacrificing function.

- Start with the Loosest Acceptable Tolerance: The default approach should be to apply a general tolerance, such as ISO 2768-mK, to the entire part. Tighter tolerances should then be applied only to the specific, critical features and dimensions that directly affect the part’s form, fit, or function. Every other dimension should remain at the standard, more economical tolerance level.

- Design Within Process Capabilities: Understand the standard capabilities of fabrication processes and design features accordingly. For example, it is known that features located very close to a bend line (e.g., within 2x the material thickness) will distort during forming. Placing a tight-tolerance hole in this zone is a classic DFM error. It forces the fabricator to form the part first and then add the hole in a secondary machining operation. A DFM-aware engineer would relocate the hole away from the bend, allowing it to be laser cut in the flat pattern with all other features in a single, low-cost step.

- Engage Fabricators Early and Often: The most valuable and underutilized resource for an engineer is the expertise of their fabrication partner. Engaging the fabricator during the design phase allows for a collaborative review of the part for manufacturability. The fabricator can identify features that will be difficult or expensive to produce and suggest alternative designs or tolerance relaxations that would significantly reduce cost without impacting performance.

4.4 The Purchasing Manager’s Playbook

A tolerance on an engineering drawing is far more than a technical detail; it is a direct instruction that dictates the required manufacturing technology, the necessary quality infrastructure, and the tier of supplier capable of producing the part. This understanding transforms the role of the purchasing manager from a price negotiator to a strategic supply chain architect.

- Question Unnecessary Precision: When a quote for a part comes back unexpectedly high, the first place to look is the drawing’s tolerances. A drawing with blanket tight tolerances is a major red flag. The purchasing team should be empowered to go back to the engineering team and ask the critical question: “Is this level of precision truly required for every single feature, or only for the key mating surfaces and mounting points?” Often, this conversation reveals that tolerances can be relaxed on non-critical features, leading to immediate and substantial cost savings.

- Recognize that Tolerances Dictate the Supply Base: A drawing with standard tolerances (e.g., ISO 2768-mK) can be competitively quoted by a wide range of capable fabrication shops. A drawing demanding multiple features with tolerances of ±0.0005′′ has drastically narrowed the field. It requires a high-precision supplier with state-of-the-art CNC machines, a temperature-controlled facility, advanced CMM inspection capabilities, and a rigorous QMS. The engineer’s tolerance specification, therefore, acts as a filter that pre-qualifies or disqualifies entire tiers of the supply base, directly impacting price and competition.

- Focus on Total Cost of Ownership, Not Piece Price: The ultimate goal is to procure a functional part at the lowest total cost. A part designed with DFM principles and relaxed, appropriate tolerances may have a slightly higher upfront engineering cost but will yield significant downstream benefits: a lower piece price, reduced scrap and rework, faster and more predictable lead times, and higher production yields. This focus on TCO is the hallmark of strategic sourcing.

The following table provides a powerful visualization of the “cost cliff” concept, linking design decisions directly to manufacturing process and cost.

Illustrative Cost Impact of Tightening Tolerances on a Fabricated Feature

| Required Tolerance | Necessary Process | Relative Cost Index |

| ±0.5mm (±0.020′′) | Standard Laser Cutting / Bending | 1.0x (Baseline) |

| ±0.2mm (±0.008′′) | Precision Laser / Bending with careful setup | 1.5x – 2.0x |

| ±0.1mm (±0.004′′) | Laser Cut + Secondary Reaming; Precision Tooling | 2.5x – 4.0x |

| ±0.05mm (±0.002′′) | CNC Machining of feature; CMM Inspection Required | 5.0x – 10.0x |

| ±0.01mm (±0.0004′′) | Precision CNC Machining (Boring); Climate Control | > 20.0x |

Conclusion: Forging a Partnership for Optimal Outcomes

Achieving the optimal balance of precision, quality, and cost in the procurement of custom stainless steel fabrications is a complex but achievable goal. It is not an outcome that can be dictated by one party, but rather one that must be cultivated through communication, collaboration, and a shared understanding of the fundamental principles that govern design and manufacturing.

This guide has synthesized the critical elements of this process, providing a unified framework for engineers, quality managers, and purchasing managers. The key takeaways are clear and actionable:

- Embrace the Language of Clarity: Move away from ambiguous title block notes and adopt the clear, unambiguous, and globally recognized language of ISO standards. Use ISO 2768 to govern machined and formed features and ISO 13920 to manage the realities of welded assemblies, applying both where necessary to create a precise and manufacturable specification.

- Respect the Material: Understand that the unique material properties of stainless steel—its high strength, higher thermal expansion, and lower thermal conductivity—present specific challenges, particularly in welding. Design and specify with these properties in mind to proactively manage distortion and ensure dimensional accuracy.

- Design for Cost-Effectiveness: Rigorously apply the principles of Design for Manufacturability. Start with the loosest acceptable tolerance and tighten specifications only where functionally necessary to control a part’s form, fit, or function. Recognize that every tightened tolerance carries an exponential cost and should be justified by a genuine performance requirement.

Ultimately, the single most effective strategy for optimizing a design for performance, manufacturability, and total cost is to engage a knowledgeable fabrication partner early in the design process. This early involvement transforms the supplier relationship from a simple transaction into a strategic partnership. By leveraging the fabricator’s deep, hands-on expertise, OEMs can identify and resolve potential manufacturing challenges before they become costly problems, ensuring the final product is not only designed right, but also built right, from the very first part.

Discuss Your Fabrication Challenge with Our Engineering Team

Partner with a fabricator that protects your investment. Submit your drawings to our team for a technical review and a comprehensive quote that reflects the true cost of quality.