Proven Since 1951

ISO 9001:2015 Certified Quality

160,000+ Sq. Ft. Facility

AWS & ASME Certified Fabrication

The Strategic Advantage of Fabricated Beams

For procurement managers and project engineers, sourcing stainless steel i-beams presents a constant battle between cost, lead time, and material specifications. Custom-fabricated beams from Northern Manufacturing directly address these core challenges.

Cost & Lead Time Reduction

Avoid the premium prices and long waits associated with specialty milled beams. Our process uses readily available stainless steel plate and sheet, which we then laser cut and robotically weld, significantly reducing costs and shortening delivery schedules.Material Flexibility

Are you struggling to find beams in Duplex 2205, AL-6XN, or Hastelloy? Our fabrication process is material-agnostic. We can create custom beams from the exact high-performance alloy your project demands, from 304L and 316L to exotic grades.Total Design Freedom

You are no longer limited by standard sizes. We manufacture beams to your precise height, flange width, and web thickness, enabling optimized engineering without compromise. This is the definition of a one-stop-shop for custom fabrication.Custom Stainless Steel I-Beam Advantages

Automation Reduces Costs

Welders are currently in short supply in the workforce. Robotic welding allows one programmer to match the output of more than 3 welders, across multiple robots and multiple shifts.

High Productivity

Our weld cycle times are often limited by how fast we can load parts into the Robot cell and hit GO. Setups often involve multiple weld fixtures for each robot, so that the robot can keep welding while parts are loaded and unloaded parallel to production.

Improved Weld Quality

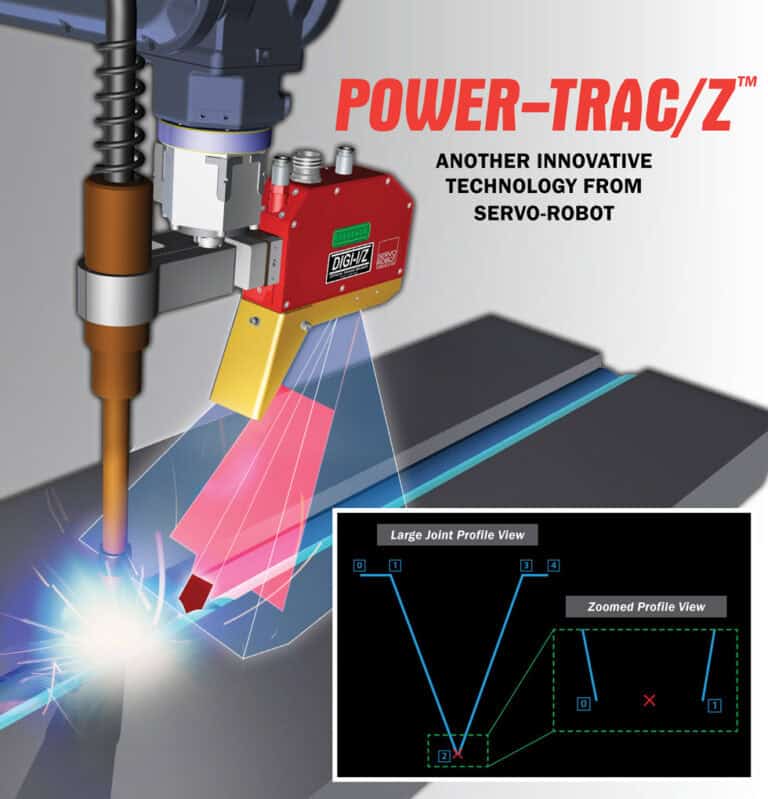

Laser vision systems allow us to push robotic weld quality to new levels. Robots have always made consistent welds, but the weld quality was only as good as the consistency of the parts entering the weld cell. No longer are robots blind and dumb. The laser vision system allows the robot to adapt the weld path to match the part tolerances, eliminating weld rework.

Robotic Welding Capabilities

Our Fabrication Process: Precision, Power, and Proof

We combine decades of craftsmanship with cutting-edge technology to produce I-beams with the structural integrity and dimensional accuracy your projects demand.

High-Speed Laser Cutting

It starts with our 12,000-watt Trumpf FiberLaser. We cut the web and flanges from your specified material grade with a typical tolerance of +/- 0.005″, ensuring perfect fit-up for welding.

Robotic Welding Cells

The components are then moved to one of our 5 robotic welding cells. Our AWS-certified procedures ensure deep, full-penetration welds that are consistent and verifiable, creating a monolithic piece with exceptional strength.

Quality & Inspection

Every fabricated beam is backed by our ISO 9001:2015 certified quality system. We can provide a complete documentation package, including:

Applications for Custom Stainless Steel I-Beams

The corrosion resistance, high strength, and hygienic properties of stainless steel make our custom-fabricated beams the ideal choice for demanding environments across numerous industries.

Food & Beverage

Sanitary supports for processing lines, tanks, and platforms where hygiene is critical.Water & Wastewater

Structural framing in corrosive environments requiring Duplex stainless or 316L grades for longevity.Power, Energy & Chemical

Robust supports for tanks, platforms, and equipment in chemical processing and power generation facilities.Architectural & Art Installations

Aesthetically pleasing structural elements where a modern, clean appearance is desired.Mining & Bulk Materials

Durable, corrosion-resistant beams for conveyors and structures in harsh material handling environments.Upgrade Your Next Project with Custom-Fabricated Beams

Stop letting standard availability dictate your design and budget. Partner with Northern Manufacturing to get the exact stainless steel I-beams you need, built with certified quality and delivered on your schedule.