ISO 9001:2015 Certified • Fabricating Since 1951

Laser Cutting Services:

Flat, Tube, and 5-Axis

Whether you need high-precision cut parts or a fully fabricated stainless assembly, Northern offers the advanced laser cutting services with over 70 years of craftsmanship to deliver components that are built right, the first time.

From simple flat blanks to complex, multi-axis cuts on formed parts, we have the specialized equipment and in-house expertise to meet your most demanding specifications.

A Complete Suite of

laser Cutting Services

We offer a full range of laser cutting services to support every stage of your project, from prototyping to full-scale production.

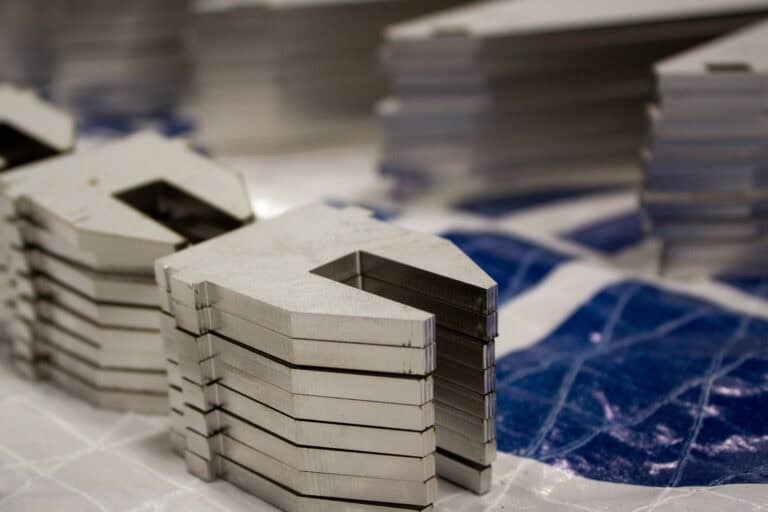

High-speed cutting for sheet and plate applications, powered by our automated Fiber Laser. We deliver clean-edged, nested parts with exceptional accuracy and material efficiency.

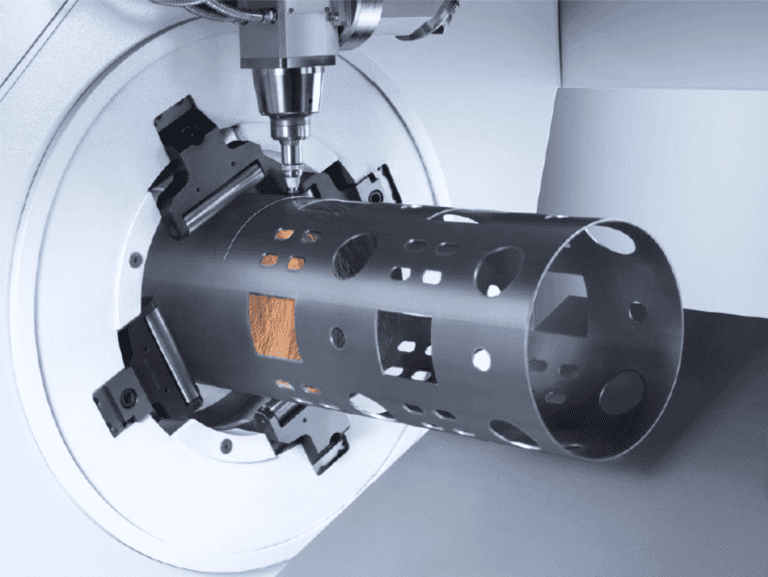

For complex geometries, 5-axis lasers provides true 3D cutting capabilities. Ideal for trimming formed parts, creating weld-prep bevels, and precisely cutting features on pre-welded assemblies, reducing the need for secondary machining.

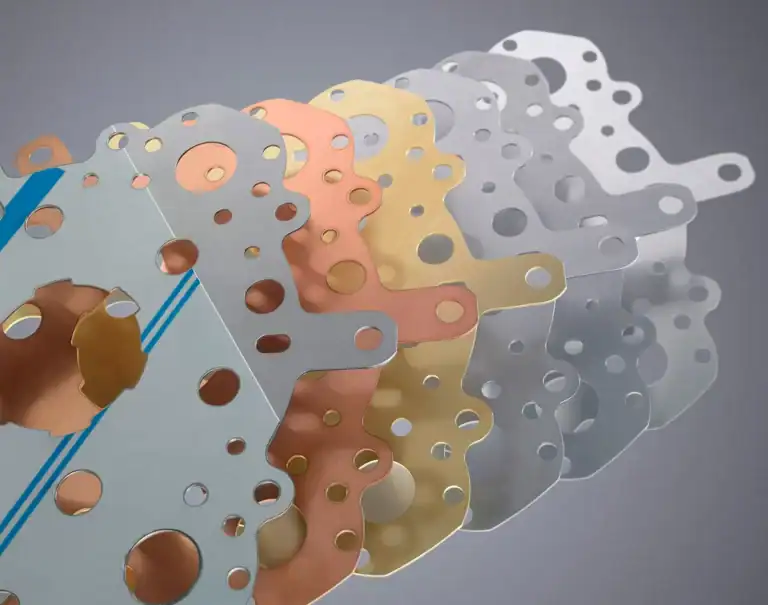

Materials We Process

Our expertise extends across a wide range of metals, with a deep specialization in stainless steel and high-nickel alloys.

|

Material Family

|

Specific Grades Handled

|

|---|---|

|

Austenitic Stainless Steels |

Common Grades: 301, 303, 304/304L, 316/316L |

|

Duplex Stainless |

Lean Duplex: 2101 LDX, 2304 |

|

High-Nickel Alloys |

AL-6XN®, Hastelloy C-22®, Hastelloy C-276®, Alloy 20 |

|

Ferritic & Martensitic Stainless Steels |

409, 410, 430, 439, 441 |

|

Carbon Steel & Aluminum |

A full range of standard grades for structural and general-purpose applications. |

Beyond the Cut:

A One-Stop-Shop for Fabrication

We are not just a cutting service; we are a full-service fabrication partner. Your laser-cut parts can move seamlessly from the laser bed to our in-house forming, welding, and finishing departments, all under one roof and managed by a single quality system.

Part Cutting and Forming Only

Perfect for shops and buyers who just need cut parts — no welding, no finishing.

Fast-turn, clean-cut blanks in stainless, aluminum, or carbon steel.

Full Stainless Fabrication

Tech-Driven Laser Cutting, Start to Finish

We don’t run on 2D prints and guesswork. Our laser cutting services are backed by a model-based workflow that ensures:

Who Uses Our Laser Cutting Services?

Fabricators

Parts drop right into your fixtures or weld jigs

OEMs

Pre-cut kits for weld or bolt-together assemblies

Food & Sanitary

Critical applications requiring smooth, clean interiors.

Machine Builders

Bracketed frames with slot-tab alignment

Contract Manufacturers

Small run parts, ready for subassembly

Automotive

Large-scale ductwork, stacks, and housings for scrubber and air handling systems.

Ready to Get Started with Our Laser Cutting Services?

Let’s turn your design into a high-quality, spec-ready component. Our team is ready to review your project and provide a comprehensive quote.