Certified Quality. Trusted Partnerships.

Precision Tube Laser Cutting Services:

From CAD to Parts, Fast

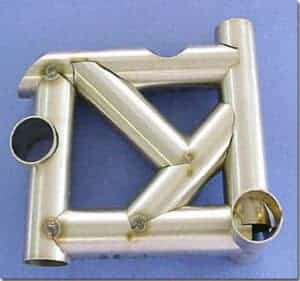

Tube laser cutting services for round, square, and rectangular pipe and tubing. Upload your CAD and get traceable, clean-cut tube parts ready for fabrication.

From simple flat blanks to complex stainless weldments—we’re built to scale with your project’s complexity.

Tube Laser Cutting Features

Unparalleled Accuracy

We hold positional accuracy to ±0.005”, enabling faster, cleaner part fit-up — whether you weld or bolt together. That’s 3x more accurate than saw-cutting.

Design in New Ways

We laser-cut complex shapes directly into your tubing — from etched alignment lines to coping, slots, tabs, and more. You save time and eliminate fixtures.

Cut Long, Cut Heavy, Cut Smart, Cut Fast

From 10” diameter tube to 30’ lengths and 25 lb/ft capacity — our tube laser handle it. You don’t need to compromise design for capability.

Tube Laser Capabilities

Shapes:

Why Choose Us for Tube Laser Cutting Services?

We offer more than just a tube laser cutting service — we’re a strategic partner to engineers, buyers, and fabricators who rely on tight tolerances, smart geometries, and fast turnarounds. Our in-house team turns your 3D models into laser-cut tube parts that fit the first time, every time.

Why it matters: Whether you’re welding, bolting, assembling, or shipping a kit of parts, we deliver the cut quality and precision that keeps your project on track.

Smart Cuts = Fast Builds

Our capabilities go beyond clean cuts — we integrate slots, tabs, copes, and alignment features directly into your parts, eliminating hours of manual layout, grinding, and guesswork.

Processing Features

Who Uses Our Tube Laser Cutting Services?

Fabricators

Parts drop right into your fixtures or weld jigs

OEMs

Pre-cut kits for weld or bolt-together assemblies

Food & Sanitary

Critical applications requiring smooth, clean interiors.

Machine Builders

Bracketed frames with slot-tab alignment

Contract Manufacturers

Small run parts, ready for subassembly

Automotive

FAI and PPAP capable. Large production runs.

Ready to Get Started with our

Tube Laser Cutting Services?

Whether you need one part, a full kit, or custom fabrication — our team will help you move fast and build smart.

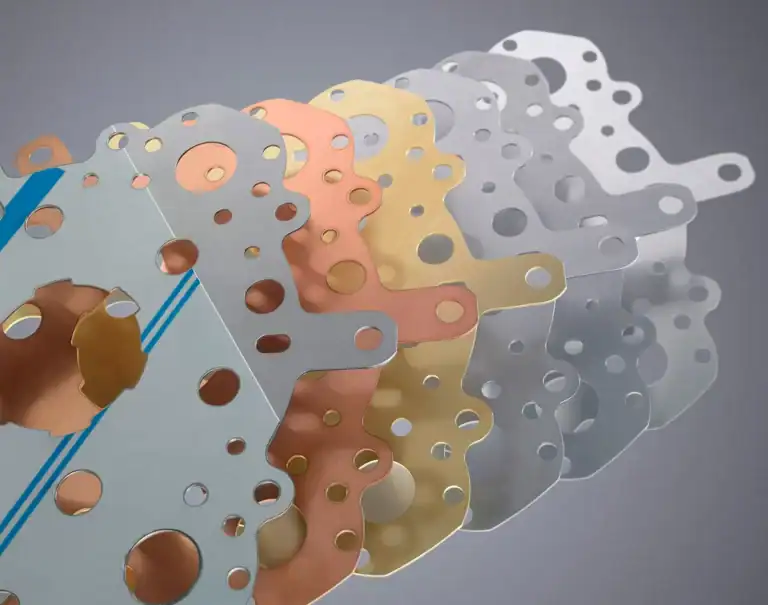

Beyond Tube: Explore All Our Laser Capabilities

High-speed fiber and CO₂ flat laser cutting for sheet, plate, and nested part jobs.

Laser welding allows full penetration welds with low heat input, perfect for stainless steel fabrication projects.