Duplex vs. 316L Stainless Steel: A Guide to Strength, Corrosion Resistance, and TCO

Are your 316L stainless steel components failing prematurely in harsh environments? Or are you forced to use thicker, heavier materials to meet structural demands, driving up costs for material, shipping, and installation? For decades, austenitic grades have been a reliable standard, but modern industrial challenges in sectors from chemical processing to wastewater treatment increasingly expose their limitations. The solution lies in a smarter, more advanced material class: duplex stainless steel.

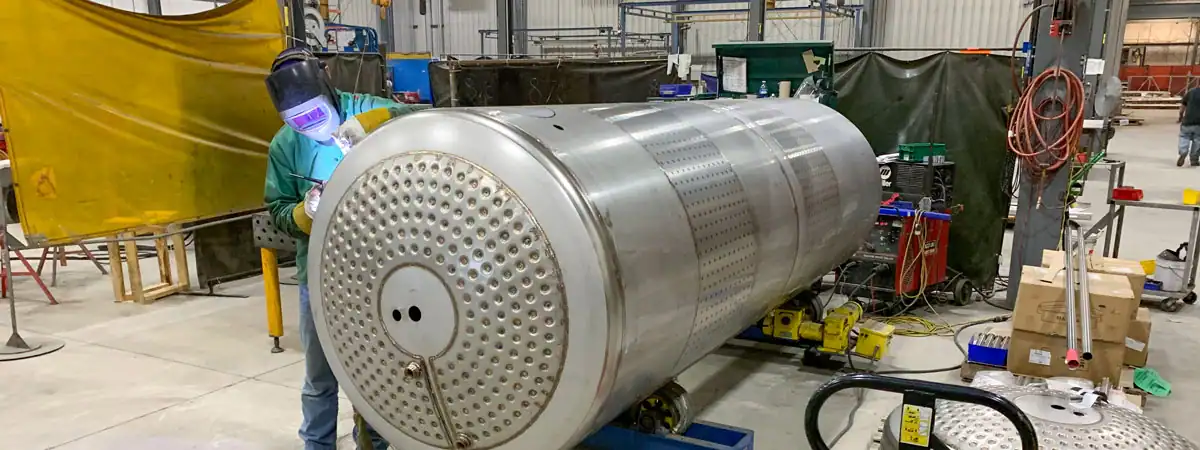

At Northern Manufacturing, we specialize in fabricating what others can’t, and that includes mastering complex materials like Duplex 2205, 2507, and 2101 LDX.

A Hybrid Powerhouse: What Makes Duplex Steel Different?

Duplex stainless steel represents a significant metallurgical advancement. Its name comes from its unique, two-phase microstructure, which is engineered to contain a balanced mixture of both austenite and ferrite crystals.

This hybrid structure combines the high strength and resistance to Stress Corrosion Cracking (SCC) from the ferritic family with the excellent toughness and broad corrosion resistance of the austenitic family (like 304 and 316). This engineered partnership creates a material that is fundamentally superior for demanding applications.

Why It Matters: The Tangible Benefits for Your Project

Translating this science into practical value reveals why duplex steel is a strategic upgrade for critical components, addressing the core challenges of both technical design and strategic sourcing.

1. Twice the Strength, Lighter Designs

The most significant advantage of duplex steel is its remarkable strength. Standard duplex grades like 2205 have a yield strength approximately double that of common austenitic grades like 316L.

What this means for your design: This superior strength allows engineers to design components with thinner walls and cross-sections—a practice known as “down-gauging”—without compromising structural integrity. A significant reduction in material thickness is often possible, leading directly to lighter structures, reduced raw material costs, and lower expenses for transportation and on-site installation.

2. Unmatched Corrosion Protection in Tough Conditions

While 316L offers good general corrosion resistance, it is vulnerable to aggressive attack in chloride-rich environments found in the chemical, power, and water treatment industries. Duplex steel is engineered to excel where these materials fail.

What this means for reliability: Duplex offers demonstrably superior resistance to pitting, crevice corrosion, and especially Stress Corrosion Cracking (SCC)—a dangerous failure mode that can cause sudden, catastrophic failure in austenitic steels. This ensures a longer, more reliable service life for critical assets like pressure vessels and tanks, preventing costly failures and project delays.

3. Smarter Spending and Long-Term Value

A material’s true cost extends beyond its price per pound. When analyzing the Total Cost of Ownership (TCO), duplex stainless steel provides a compelling economic case.

What this means for your budget and supply chain: Duplex steel’s chemistry uses significantly less nickel—an expensive and notoriously volatile commodity that heavily influences the price of 316L. This provides greater price stability for more predictable project budgeting. Furthermore, its enhanced durability dramatically reduces the need for maintenance, repairs, and premature replacement, de-risking the supply chain and delivering the lowest total cost over the asset’s entire lifecycle.

The Northern Manufacturing Difference: Fabrication Expertise is Key

Specifying duplex stainless steel is the first step, but unlocking its full potential requires a fabricator who understands the science. Preserving its unique ferrite-austenite balance during welding and forming demands a higher level of process control than for standard stainless steels.

Since 1951, Northern Manufacturing has delivered intricate, spec-ready parts by blending old-world craftsmanship with cutting-edge technology. Our expertise is verifiable:

- Certified Processes: Our ISO 9001:2015 certified quality management system ensures every step is controlled and documented.

- Expert Welders: Our 60+ certified welders and procedures are qualified in accordance with AWS and ASME BPVC Section IX, giving us the deep expertise needed to properly weld duplex steels.

- In-House Verification: With an on-staff Certified Welding Inspector (CWI) and ASNT SNT-TC-1A Level III personnel, we validate the integrity of every component before it leaves our 160,000 sq. ft. facility.

Discuss Your Fabrication Challenge with Our Engineering Team

Partner with a fabricator that protects your investment. Submit your drawings to our team for a technical review and a comprehensive quote that reflects the true cost of quality.