De-Risking Your Design: The Path to Budget and Schedule Certainty

We understand the greatest risks for any architectural project are delays, budget overruns, and compromises to the design vision. Our entire process is engineered to mitigate these threats, providing the certainty and reliability you need from a fabrication partner.

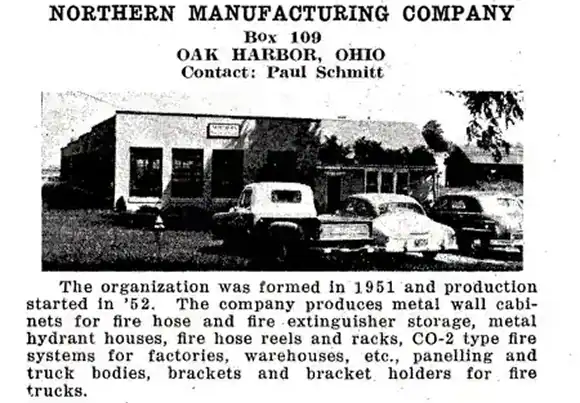

Founded in 1951 – 74 Years of Fabrication Experience

160+ Team Members 60+ AWS-Certified Welders

160,000 sq. ft. Facility with Stainless-Dedicated Space

ISO 9001 Certified + AWS Qualified Team

Lasers Welding, Tube Cutting, Robotic Welding

In-House Pickling & Passivation

From Digital Complexity to Physical Reality: Our Design-Assist Approach

We are more than fabricators; we are the technical partner you need to solve complex design challenges. Our Design-Assist philosophy integrates our expertise early in your process to review constructability, prevent costly delays, and ensure even the most ambitious architectural visions are buildable.Collaborative Design-Assist

We engage early in the design phase to optimize details and ensure constructability, preventing the RFIs and delays common in traditional bid-build projects.Advanced Technology & Master Craftsmanship

We use state-of-the-art 5-axis laser cutting and precision forming, wielded by over 160 skilled craftsmen, to accurately fabricate complex and parametric geometry.Aesthetic & Certified Welding

Our AWS-certified welders are masters of GTAW, delivering the flawless, clean welds required for Architecturally Exposed Structural Steel (AESS) and other visible features.Frequently Asked Questions

Project Gallery: Architectural & Art Installations

Loading Images

Partner with a Fabrication Expert for Your Next Project

From vision to flawless execution. We are your collaborative partner, ready to de-risk your project and help you build something extraordinary.