Why OQE Matters for OEMs

Every fabricated component we deliver becomes a part of your final product and your brand. A failure in the field can impact reputation and increase Total Cost of Ownership (TCO) through rework, project delays, and warranty claims. Our OQE process provides verifiable proof of compliance, protecting your brand and your bottom line.

Advanced Verification Technologies & Processes

Each tool contributes a vital dataset to your project’s Quality Dossier.

Positive Material Identification (PMI): Verifying Material Certainty

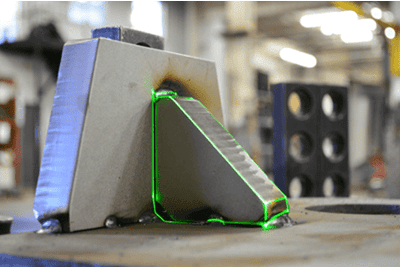

Laser Projector Layouts: Error‑Proofing Assembly

Laser Weld Inspection: Our Digital CWI

Mobile AR Inspection:

Accelerating Quality Verification

3D Model‑Based Inspection:

From the Largest Scale to the Smallest Detail

This extends our Model‑Based Planning process, maintaining digital continuity from design to verification.

Our Commitment to Measurement Integrity

All equipment follows a strict calibration schedule traceable to NIST per ISO 9001 requirements.

Your Comprehensive Quality Report

Dimensional conformance

PolyWorks reports with reported deviations; typical measurement uncertainty on the order of ~±0.15 mm (setup‑dependent).Weld evidence

WiKi‑Scan quantitative data with code‑referenced pass/fail.Material traceability

PMI reports and full MTR chain‑of‑custody.Assembly completeness

AR overlay screenshots/checklist.Quality records

Project‑specific ITP with sign‑offs and hold points, plus a Certificate of Conformance—backed by the full evidence set.Frequently Asked Questions

Ready to De-Risk Your Next Project?

Trust is built on proof. Our advanced inspection and verification processes provide the objective, auditable data you need to be certain every component arrives spec-ready and audit-ready.

Eliminate uncertainty and ensure project success from the start. Upload your drawings or schedule a complimentary 15-minute technical review with our engineering team to see how our quality systems can protect your project, your timeline, and your reputation.