Why Model‑Based Planning?

Traditional job-shop workflows rely on re-keying data and tribal knowledge. We start with your native 3D CAD and keep it in the driver’s seat—so geometry, tolerances, and materials flow automatically into quoting, planning, and inspection. The result is shorter lead times, fewer hand-offs, and clear traceability back to your original requirements. While not every step is automated, the more stages we connect to the model, the less room there is for human-induced variation.

Designed for Spec Compliance

A single missed requirement can lead to significant project delays and costly rework. Our process is designed to mitigate this risk by ensuring every technical specification is captured, tracked, and verified.

How We Do It: We use AI-assisted technology to parse your technical documents, building a preliminary Inspection & Test Plan (ITP). Crucially, our quality experts—including our on-staff Certified Welding Inspector (CWI) and ASNT SNT-TC-1A Level III personnel—then review and validate this plan, creating a human-verified system that combines technological precision with decades of fabrication experience.

Your Advantage: You receive an auditable plan that protects your project from expensive oversights and guarantees every component is spec-ready.

From Accurate Budgets

to First-Time Fit

Your project’s success depends on reliable pricing and components that fit correctly during installation. Our 3D model-driven workflow is built to deliver both.

How We Do It: A machine learning algorithm analyzes your 3D model to generate highly accurate cost estimates. On the shop floor, our 160+ craftsmen work from clear 3D models on screens, preventing the errors common with complex 2D drawings.

Your Advantage: Get fast, data-driven quotes you can trust and metrology-grade evidence that supports a successful first-time fit, eliminating costly on-site rework.

Shorter Lead Times

for Custom Projects

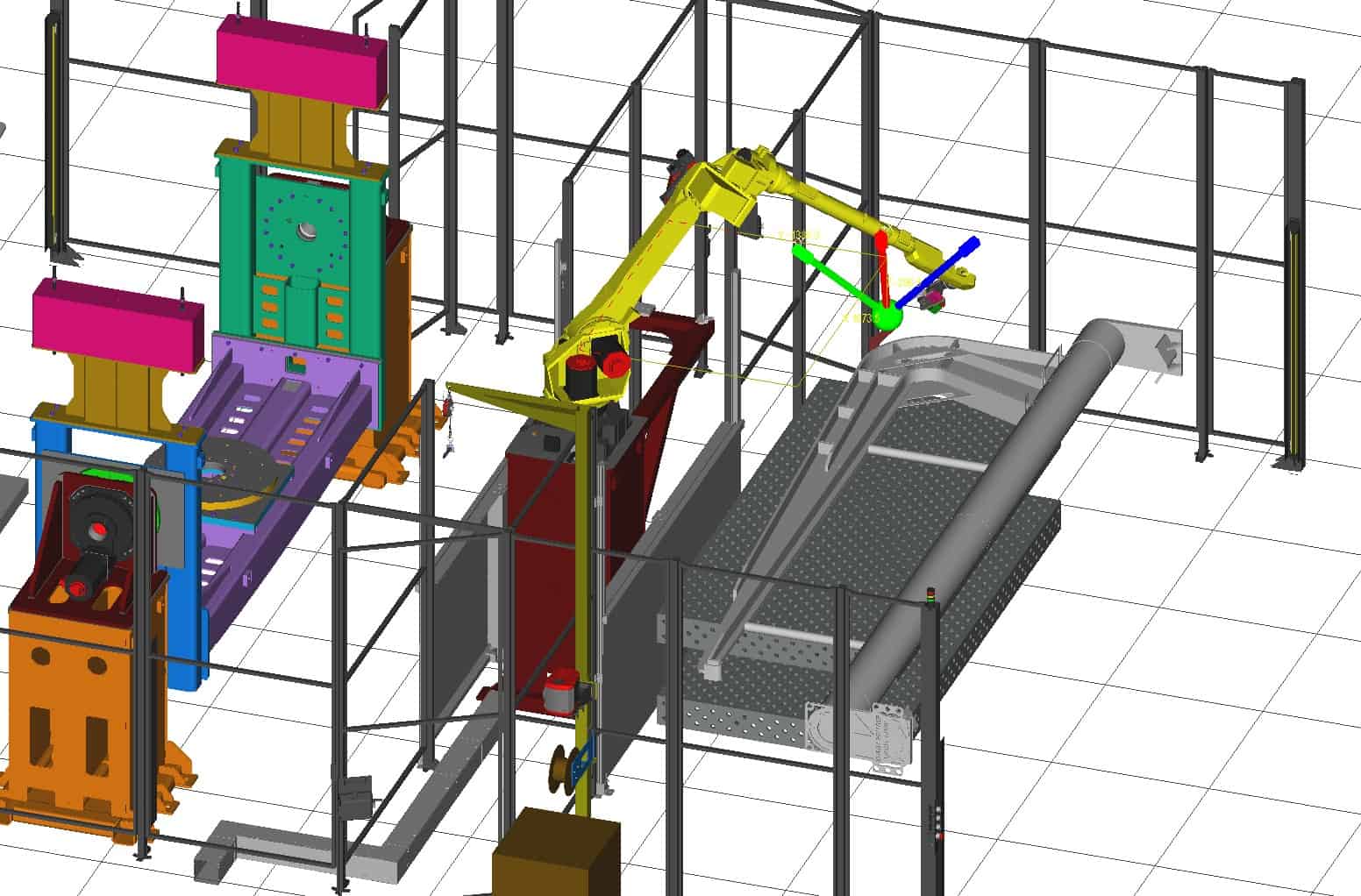

In the high-mix, low-volume world of custom equipment, programming downtime can derail project schedules. We use technology to maximize machine uptime and accelerate delivery.

Your Advantage: Our investment in OLP maximizes our efficiency, helping to reduce lead times for your critical custom projects.

How We Do It: We utilize Offline Robotic Programming (OLP) to create and simulate complex robotic welding and forming programs in a virtual environment. This allows our physical machines to continue running other jobs, drastically reducing non-productive downtime.

Proactive Issue Resolution That Protects Your Schedule

Working with a “black box” supplier—where problems are hidden until it’s too late—is a major source of risk. We believe in total transparency.

Your Advantage: We function as a transparent, self-correcting partner, anticipating and resolving potential issues before they can impact your delivery schedule.

How We Do It: We use a powerful business intelligence platform to integrate data from across our 160,000 sq. ft. facility into real-time dashboards. This gives our management team instant visibility to identify and address potential bottlenecks proactively.

De-Risk Your Next Project

Since 1951, we’ve built our reputation on turning complex challenges into spec-ready components. Our model-based planning is the next evolution of that promise. We provide a complete quality dossier with every project, giving you total confidence and a permanent record for your compliance archives. We understand the proprietary nature of your designs and operate under NDAs to ensure strict confidentiality.